- アフリカ人

- アルバニア語

- アムハラ語

- アラビア語

- アルメニア語

- アゼルバイジャン語

- バスク語

- ベラルーシ語

- ベンガル語

- ボスニア語

- ブルガリア語

- カタロニア語

- セブアノ語

- コルシカ

- クロアチア語

- チェコ語

- デンマーク語

- オランダの

- 英語

- エスペラント

- エストニア語

- フィンランド語

- フランス語

- フリジア語

- ガリシア語

- ジョージア語

- ドイツ人

- ギリシャ語

- グジャラート語

- ハイチ語

- ハウサ語

- ハワイアン

- ヘブライ語

- いいえ

- ミャオ族

- ハンガリー語

- アイスランド語

- イボ語

- インドネシア語

- アイルランド人

- イタリアの

- 日本語

- ジャワ語

- カンナダ語

- カザフ語

- クメール語

- ルワンダ語

- 韓国語

- クルド

- キルギス語

- 結核

- ラテン

- ラトビア語

- リトアニア語

- ルクセンブルク語

- マケドニアの

- マルガシ

- マレー語

- マラヤーラム語

- マルタ語

- マオリ語

- マラーティー語

- モンゴル語

- ミャンマー

- ネパール語

- ノルウェー語

- ノルウェー語

- オック語

- パシュトゥー語

- ペルシャ語

- 研磨

- ポルトガル語

- パンジャブ語

- ルーマニア語

- ロシア

- サモア語

- スコットランド・ゲール語

- セルビア語

- 英語

- ショナ語

- シンディー語

- シンハラ語

- スロバキア語

- スロベニア語

- ソマリ語

- スペイン語

- スンダ人

- スワヒリ語

- スウェーデンの

- タガログ語

- タジク語

- タミル語

- タタール語

- テルグ語

- タイ語

- トルコ語

- トルクメン語

- ウクライナ語

- ウルドゥー語

- ウイグル

- ウズベク語

- ベトナム語

- ウェールズ語

- ヘルプ

- イディッシュ語

- ヨルバ語

- ズールー語

2月 . 26, 2025 13:56 リストに戻る

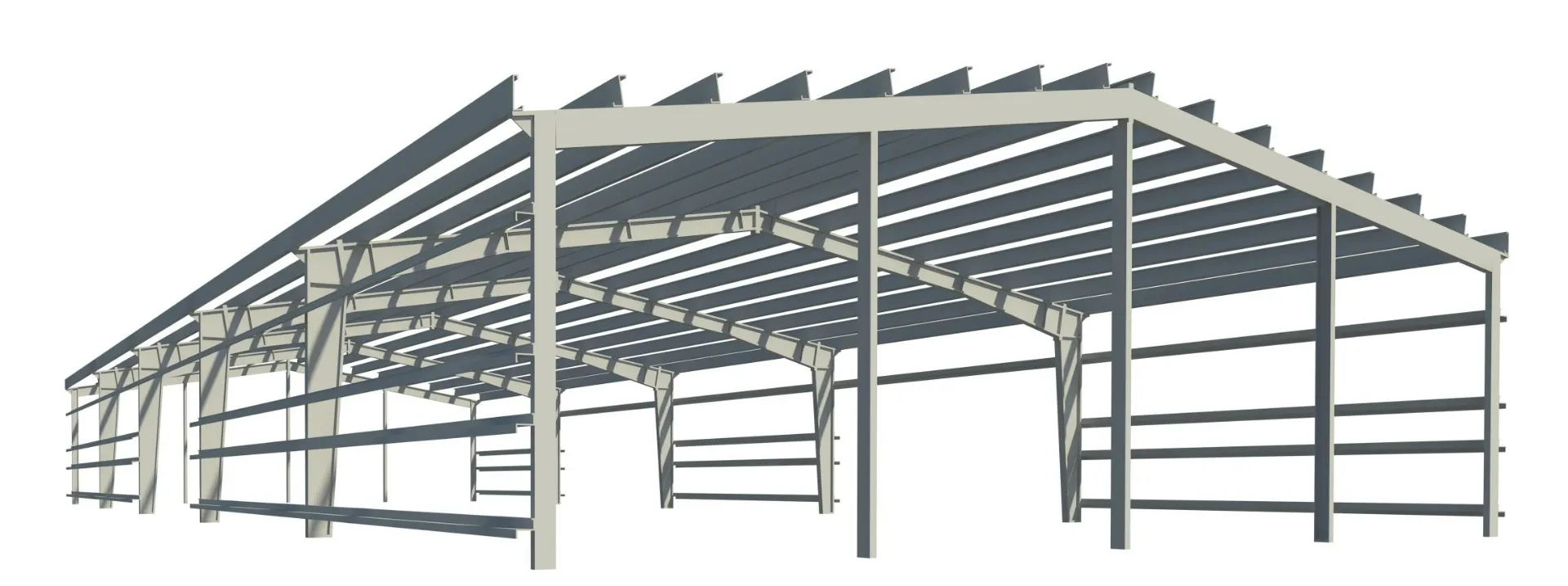

In the modern chicken industry, the choice of chicken house is very important, it is directly related to the cost of breeding, the health of chickens, and the efficiency of breeding. At present, the common types of chicken coops on the market mainly include prefabricated steel frame chicken coop and traditional coops. Today, we will take an in-depth comparison of these two chicken coops, while focusing on the unique charm of the H.J SHUNDA prefabricated steel frame chicken coop.

Steel Frame Chicken Coop Has Cost Effective

Most of the traditional chicken houses use brick and tile structures, and their construction cost is relatively high. From the point of view of material costs, the price of red brick, cement and so on is not low, coupled with transportation, labor, and other costs, the cost per square meter is also a big expense. The prefabricated steel structure house of H.J SHUNDA adopts the mode of factory prefabrication and on-site assembly. It can be seen that prefabricated metal agricultural buildings can greatly reduce the material cost and labor costs, which greatly releases the financial pressure of farmers in the early stage.

Steel Frame Chicken Coop Has Shorter Construction Cycle

Compared with metal agricultural buildings, the construction process of traditional chicken coops is complicated, and it takes a lot of time from foundation construction, wall building, and roof construction to installation of internal facilities. In case of force majeure factors such as bad weather, the construction period will be further extended. All components of H.J SHUNDA prefabricated steel structure house are prefabricated in the factory, and only need to be assembled on site, just like building blocks. The construction of a traditional chicken coop can take months, but now H.J SHUNDA prefabricated steel structure house can complete the main body in just a few days, greatly shortening the construction cycle and allowing farmers to get into production faster.

Steel Frame Chicken Coop Has Good Performance

Thermal insulation: H.J SHUNDA prefabricated steel structure building uses high-quality thermal insulation materials, such as high-efficiency foam sandwich panels, whose thermal insulation performance far exceeds that of traditional brick walls. The experimental data show that the insulation effect of a 10cm insulation wall can reach the insulation performance of a 50cm brick wall.

Ventilation and space utilization: The use of a reasonable vertical column support structure increases the internal space of the steel frame chicken coop and is more conducive to air circulation. Good ventilation conditions can effectively reduce the humidity and harmful gas concentration in the steel frame chicken coop, reducing the risk of disease. However, the traditional chicken coop often has certain limitations in space layout and ventilation design.

Epidemic prevention and cleaning: The surface of the prefabricated steel structure house is smooth and flat, and bacteria and viruses are difficult to attach and breed. Daily cleaning, easy to wash and disinfection, coupled with timely cleaning of chicken feces, greatly reduce the risk of spread of bacteria in the steel frame chicken coop.

In summary, whether it is from the perspective of cost control, construction cycle, or performance, H.J SHUNDA prefabricated steel frame chicken coop has shown obvious advantages and is the ideal choice for the modern chicken industry. If you are thinking of building a chicken coop, choose H.J SHUNDA agricultural building manufacturer, and start a new chapter in efficient farming!

-

Steel Frame Modular Construction for Housing

ニュースAug.07,2025

-

Steel Construction Factory Processes

ニュースAug.07,2025

-

Portal Frame Shed for Sale: Delivery Options

ニュースAug.07,2025

-

Metal Workshops for Sale: Insulation Solutions

ニュースAug.07,2025

-

Metal Steel Building Manufacturers: Post-Construction Services

ニュースAug.07,2025

-

Metal Garage Shed Kits: Size Options

ニュースAug.07,2025

製品カテゴリー

最新ニュース

We have a professional design team and an excellent production and construction team.