- Aferika

- Alapania

- Amharic

- Alapi

- Armenian

- Azerbaijani

- Basque

- Pelalusiana

- Bengali

- Bosnian

- Bulgarian

- Katalana

- Sepuano

- Kosikana

- Croatian

- Czech

- Danish

- Siamani

- Igilisi

- Eseperano

- Estonian

- Finnish

- Falani

- Frisian

- Galician

- Georgian

- Siamani

- Greek

- Gujarati

- Haiti Kereole

- Hausa

- Havaii

- Eperu

- Leai

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- Aialani

- Italia

- Iapani

- Javanese

- Kannada

- Kasaka

- Khmer

- Rwanda

- Kolea

- Kutisa

- Kirikisi

- TB

- Latina

- Latvian

- Lituaniana

- Lusemipoukisi

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maoli

- Marathi

- Mokoliana

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pasato

- Persian

- Polish

- Portuguese

- Punitapi

- Lomani

- Lusia

- Samoa

- Sikotilani Gaelic

- Serbian

- Igilisi

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sipaniolo

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Fa'a Thai

- Turkish

- tamaloloa Take

- Ukaraina

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Uelese

- Fesoasoani

- Yiddish

- Yoruba

- Zulu

Aug . 07, 2025 09:39 Toe fo'i i le lisi

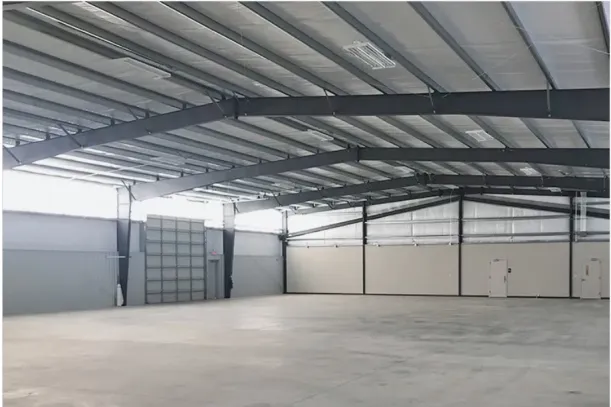

The modern industrial sector is prioritizing energy efficiency, with factory direct metal buildings leading this transformation. These structures, including specialized industrial metal storage sheds, combine durability with innovative energy-saving features. Their superior thermal performance makes industrial metal buildings ideal for businesses seeking to reduce operational costs while maintaining optimal workspace conditions.

Energy Efficiency in Factory Direct Metal Buildings

Factory direct metal buildings incorporate cutting-edge technologies to maximize energy performance:

- Advanced insulation systems in factory direct metal buildingscreate superior thermal barriers

• Cool roof technology reduces cooling loads by up to 30% in hot climates

• Precision engineering minimizes air infiltration, a major source of energy loss

• Solar-ready designs allow easy integration of renewable energy systems

• Energy modeling ensures optimal performance for each specific application

Thermal Performance of Industrial Metal Buildings

Industrial metal buildings achieve exceptional thermal efficiency through:

- Radiant barrier systems that reflect up to 97% of radiant heat

• Continuous insulation packages eliminating thermal bridges

• Moisture-resistant construction preventing insulation degradation

• Temperature-stable environments reducing HVAC workload

• Adaptive designs accommodating future efficiency upgrades

Sustainable Features in Industrial Metal Storage Sheds

Industrial metal storage sheds incorporate numerous sustainable elements:

- High recycled steel content reducing embodied energy

• Strategic daylighting minimizing artificial lighting needs

• Optimized ventilation promoting passive cooling strategies

• Durable, reflective finishes resisting weathering

• Structural designs allowing for future energy improvements

Cost Savings of Factory Direct Metal Buildings

Factory direct metal buildings deliver significant financial benefits:

- Lower utility costs from reduced energy consumption

• Decreased maintenance expenses due to durable components

• Potential tax incentives for energy-efficient construction

• Higher property values for certified efficient buildings

• Reduced mechanical system costs from lower capacity needs

Innovative Technologies for Industrial Metal Buildings

Industrial metal buildings now feature cutting-edge solutions:

- Smart automation systems optimizing energy usage patterns

• Phase-change materials stabilizing interior temperatures

• Integrated renewable energy systems complementing designs

• Advanced air sealing exceeding code requirements

• Custom engineering for maximum efficiency

Factory Direct Metal Buildings FAQS

Q: How do factory direct metal buildings differ from traditional industrial metal buildings in terms of customization?

A: Factory direct metal buildings offer streamlined customization through direct manufacturer partnerships, allowing clients to tailor designs (e.g., size, roofing, door placements) without intermediary markups. Traditional industrial metal buildings may involve more complex customization processes with contractors, often leading to higher costs and longer lead times. Factory-direct models simplify this by integrating engineering and fabrication in-house, ensuring quicker turnarounds for unique industrial needs.

Q: What key factors should be considered when selecting industrial metal storage sheds from factory direct metal buildings providers?

A: When choosing industrial metal storage sheds from factory-direct suppliers, assess material thickness (e.g., 12-14 gauge steel for durability), corrosion resistance (galvanized coatings for coastal areas), and load-bearing capacities (snow/wind ratings). Factory-direct providers often offer pre-engineered kits with customizable features like ventilation systems or shelving, but ensure the design complies with local building codes—especially for industrial zones requiring fire ratings or seismic resilience.

Q: How does the pricing of factory direct metal buildings compare to non-direct options for industrial metal buildings?

A: Factory direct metal buildings typically cost 10-30% less than non-direct models due to eliminated distributor markups. For industrial metal buildings, this savings is significant in large-scale projects (e.g., warehouses or manufacturing plants). Direct providers also offer transparent pricing, breaking down costs for materials, fabrication, and delivery—unlike indirect channels where hidden fees may inflate budgets. Customization costs remain competitive due to in-house manufacturing capabilities.

Q: Can factory direct metal buildings be integrated with industrial metal storage sheds to form a cohesive complex?

A: Yes—factory-direct providers often design industrial metal storage sheds as annexes to main industrial metal buildings, using matching steel grades and architectural elements (e.g., roofing profiles or siding colors). For example, a manufacturing plant can connect storage sheds via enclosed walkways, with shared foundations and utility systems. Factory-direct teams coordinate these integrations during the design phase, ensuring structural consistency and operational efficiency.

Q: What maintenance protocols are unique to industrial metal storage sheds versus other factory direct metal buildings?

A: Industrial metal storage sheds require focused maintenance on seals and fasteners, as their smaller size often exposes joints to weathering. Unlike larger factory direct metal buildings with built-in drainage systems, sheds may need periodic checks for roof leaks or gutter clogs. Factory-direct providers typically recommend annual inspections for rust on exposed edges (especially in saltwater environments) and resealing door thresholds to prevent moisture ingress—protocols that differ from maintenance plans for larger industrial structures.

Welcome to Hebei HongJi Shunda Steel Structure Engineering Co., Ltd., Since 2000, we’ve redefined steel engineering on our 52,000㎡ campus, fueled by a USD$2.5M commitment to innovation. Specializing in steel warehouses, workshops, and eco-homes, we blend global design concepts with cost-smart raw material strategies. Our pro teams deliver end-to-end solutions—from blueprint to installation—crafting green, high-performance structures that stand the test of time. Every weld, every panel, precision-perfected. Unlock your steel vision at www.hongjishunda.com

-

Steel Frame Modular Construction for Housing

Tala FouAug.07,2025

-

Steel Construction Factory Processes

Tala FouAug.07,2025

-

Portal Frame Shed for Sale: Delivery Options

Tala FouAug.07,2025

-

Metal Workshops for Sale: Insulation Solutions

Tala FouAug.07,2025

-

Metal Steel Building Manufacturers: Post-Construction Services

Tala FouAug.07,2025

-

Metal Garage Shed Kits: Size Options

Tala FouAug.07,2025

Vaega o oloa

La Tatou Tala Fou

We have a professional design team and an excellent production and construction team.