- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Kvě . 31, 2025 11:01 Back to list

- Market Growth and Statistical Performance of Prefab Structures

- Engineering Superiority in Modern Steel Construction

- Manufacturer Comparison: Specifications & Value Analysis

- Advanced Customization Options for Varied Applications

- Technical Implementation Process Breakdown

- Diverse Industry Implementation Case Studies

- Future-Proofing Operations with Steel Solutions

(prefab steel shop)

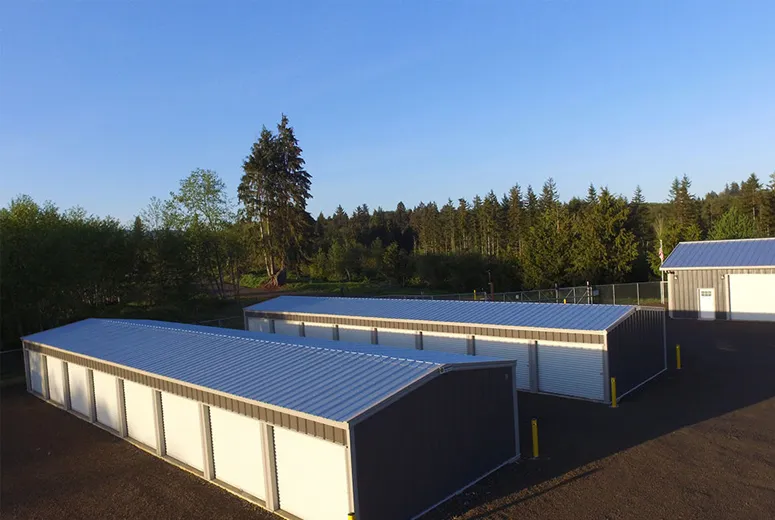

How Prefab Steel Shops Transform Industrial Workspaces

Across commercial sectors, prefab steel shop

buildings represent the most significant evolution in industrial infrastructure development. According to Market Research Future, structural steel framing adoption has grown 22% annually since 2020 as enterprises replace traditional construction methods. These engineered solutions consistently demonstrate 30-50% shorter project timelines versus conventional building techniques while simultaneously reducing waste by up to 40%. Fabricators now incorporate sophisticated BIM modeling to ensure millimeter precision before manufacturing begins, establishing new benchmarks for accuracy throughout the construction sector.

Engineering Superiority in Modern Construction

Today's prefab metal shop buildings integrate transformative engineering characteristics. High-tensile galvanized steel alloys (G90 coating) provide exceptional corrosion resistance exceeding 50 years, while integrated thermal break systems reduce energy expenditure by 25-40% compared to outdated designs. Advanced portal frame configurations enable clear spans up to 300 feet without supporting columns, delivering unobstructed operational space. Structural integrity remains uncompromised under extreme conditions, with certified wind resistance ratings of 170+ mph and snow load capacities beyond 40 psf - performance metrics that traditional wood-framed structures cannot match.

Manufacturer Comparison Analysis

| Manufacturer | Warranty | Material Grade | Standard Lead Time | Price/Sq Ft |

|---|---|---|---|---|

| SteelMaster | 40 years | ASTM A653 (G-90) | 6-8 weeks | $19.50 |

| Armstrong Steel | 35 years | ASTM A792 (AZ50) | 9-12 weeks | $22.75 |

| General Steel | 50 years | ASTM A875 (Galvalume) | 5-7 weeks | $24.30 |

Contractors should evaluate load-bearing specifications beyond price considerations. The highest-performing prefab metal shop kits incorporate 14-gauge primary framing with 26-gauge secondary components, exceeding most municipal code requirements. Secondary considerations include proprietary connection systems minimizing onsite assembly duration and specialized anti-condensation barriers preventing moisture accumulation - critical features often overlooked during vendor selection but impacting long-term functionality.

Advanced Configuration Parameters

Leading suppliers now provide extensive customization options for prefab metal shop kits. Beyond dimensional specifications (width, length, eave height), professionals can select from multiple roof configurations including vertical rib, PBR, and standing seam designs with varying pitch angles from 1:12 to 4:12. Advanced manufacturers implement modular partition systems enabling future expansions without structural compromises. Mechanical integration points are precision-engineered during fabrication for HVAC, plumbing, and electrical systems, significantly reducing retrofit expenses and installation timelines. Optional enhancements like translucent wall panels achieve 15% natural lighting penetration while maintaining thermal efficiency.

Technical Implementation Sequence

Successful installation follows a meticulous six-phase process beginning with geotechnical analysis ensuring proper soil compaction and foundation design. Engineered concrete piers typically require 28-day curing before structural assembly commences. Certified crews then systematically erect primary frames using specialized torque-controlled equipment to exact manufacturer specifications. Secondary framing and roof purlins follow in sequenced installation patterns verified by laser alignment. The entire envelope installation typically concludes within 15-30 days depending on structure complexity.

Industry-Specific Applications

Agricultural operations in Midwest regions utilize 80' clear-span designs for equipment storage, reporting 23% lower maintenance costs compared to pole barns. Manufacturing facilities increasingly adopt insulated panel systems achieving STC-42 acoustic ratings for noise-sensitive processes. A Wisconsin equipment dealer constructed a 12,000 sq ft facility in 18 days using prefabricated components, accelerating their operational timeline by five months. Logistics companies implementing these structures reduced loading dock congestion by 40% through optimized traffic flow designs, while contractors executing commercial projects value the 65% reduction in onsite labor requirements.

Strategic Advantages of Prefab Steel Shop Solutions

The structural superiority of prefab metal shop buildings provides tangible operational benefits that compound over decades. Properly maintained steel structures demonstrate 100+ year lifespans - three times longer than conventional construction - with minimal degradation to structural integrity. Maintenance expenditures remain exceptionally predictable, with cleaning and inspection costs averaging $0.12/sq ft annually. Businesses incorporating expansion provisions during initial design report 30% cost savings versus future stand-alone construction. For enterprises prioritizing resilience, efficiency, and lifecycle value, these engineered solutions represent the definitive standard in industrial infrastructure.

(prefab steel shop)

FAQS on prefab steel shop

Q: What are the advantages of prefab steel shops?

A: Prefab steel shops offer durability, fast installation, and cost efficiency. They are resistant to pests, fire, and harsh weather, making them ideal for industrial use.

Q: Can prefab metal shop buildings be customized?

A: Yes, prefab metal shop buildings can be tailored in size, layout, doors, and roofing. Many manufacturers offer design flexibility to meet specific operational needs.

Q: How long do prefab metal shop kits last?

A: With proper maintenance, prefab metal shop kits can last 30+ years. High-quality steel and protective coatings prevent rust and structural degradation.

Q: Are prefab steel shops faster to build than traditional structures?

A: Yes, prefab steel shops are pre-engineered and assembled on-site, reducing construction time by 30-50% compared to conventional building methods.

Q: Are prefab metal shop kits cost-effective?

A: Prefab metal shop kits minimize labor and material waste, lowering upfront costs. Long-term savings come from reduced maintenance and energy expenses.

-

The Rise of Prefabricated Metal Structures in Modern Industry

NewsJul.28,2025

-

The Landscape of Prefabricated Metal Building Solutions

NewsJul.28,2025

-

Analyzing Costs and Pricing Dynamics in Prefabricated Steel and Metal Buildings

NewsJul.28,2025

-

Advance Industrial Infrastructure with Prefabricated Steel Solutions

NewsJul.28,2025

-

Advancing Industrial Infrastructure with Prefabricated Metal Warehousing Solutions

NewsJul.28,2025

-

Advancing Industrial and Commercial Spaces with Prefabricated Steel Solutions

NewsJul.28,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.