- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 29, 2025 17:00 Back to list

With growing demands for durability, design flexibility, energy efficiency, and cost-effectiveness, metal buildings for residential use have surged as a leading construction trend worldwide. Combining advances in engineered steel, specialized coatings, and rapid modular assembly, today’s homes, handrails, and structures outperform conventional wood or brick builds.

Featuring highly customizable solutions such as Engineered Steel Metal Garage Kits (learn more), the sector now achieves ultra-fast delivery timelines, robust protective standards, and stylish aesthetics tailored to modern living.

1. Market & Industry Trends — Why Metal Buildings Dominate Residential Construction

- 2023–2028 CAGR: Global metal buildings for residential use market projected at 8.1% annual growth (source).

- Key Drivers: Fire resistance, anti-corrosion, low long-term cost, and rapid assembly ability.

- Top Residential Applications: Villas, eco-homes, tiny houses, garden cottages, energy-neutral homes, and garages.

- Technological Trends: Pre-engineered kits, smart insulation, advanced panelization (CNC, laser cut), and ANSI/ISO-certified components.

2. Core Technical Parameters of Metal Buildings for Residential Use

| Specification | Typical Value | Industry Standard | Performance/Remark |

|---|---|---|---|

| Main Material | Q355B/S355JR Carbon Steel, 304/316 Stainless Steel | GB/T700, EN10025, ASTM-A36, ASTM-A992, ASTM A240 | Superior strength, anticorrosive alloy optional |

| Wall/Roof Panel | Galvanized, Al-Zn Alloy, 0.4–1.0mm | ASTM A653, JIS G3302 | Self-cleaning, Kynar/PVC/PE coatings |

| Insulation | PU Foam / Glass Wool / Rockwool 50–120mm | EN13501 (Fire), ASTM C518 (thermal) | A1 fireproof, R-value up to 40 |

| Wind/Seismic Rating | Wind 35 m/s, Earthquake 9° | IBC 2015, GB50011, EN1998-1 | Meets global residential codes |

| Lifespan | > 50 years | ISO 9223, ASTM G87 | 20+ years warranty possible |

| Metal Handrails | Φ32–50mm 304 Stainless, H112 Aluminum | ISO 3506, EN1993-1-8 | Anti-slip, anti-rust, modular design |

- Density: 7.85 g/cm³ (Steel), 8.0 g/cm³ (Stainless)

- Yield Strength: 355–450 MPa

- Thermal Conductivity (Panels): 0.023–0.039 W/m•K

- Fire Resistance: A1–A2 S1-d0 (non-combustible, per EN classification)

3. Visualizing Technology Specifications: ECharts Interactive Data

4. Manufacturing Process Visualized: Engineered Steel Metal Garage Kits

5. Technical Advantages: Why Choose Metal Buildings for Residential Use?

- Durability: With a design life exceeding 50 years, premium metal buildings for residential use withstand extreme wind, seismic, and snow loads.

- Fire Safety: Metal shells and metal handrails residential products are naturally fire-resistant and do not propagate flames (A1 fire rating).

- Low Maintenance: Engineered coatings (PVDF, Galvalume) prevent corrosion; minimal repainting needed over decades.

- Customization: Modular frames, rich facade styles, multiple insulation/fitting options. Garage, loft, and accessory dwelling units are all possible.

- Speed of Delivery: Pre-engineered kits like Engineered Steel Metal Garage Kits can be delivered and installed in less than two weeks for typical homes.

- Environmental Performance: High recyclability, minimized on-site waste, and improved energy-efficiency due to integrated insulation.

- Certifications: All products strictly follow ISO, ANSI, ASTM, CE standards for safety, materials, and indoor air quality.

6. Manufacturer Comparison: Metal vs Traditional & Key Suppliers

| Engineered Steel Metal Garage Kits | Timber Framed Home | Concrete Block House | |

|---|---|---|---|

| Material & Lifespan | Steel, 50+ yrs | Treated Wood, 25–35 yrs | Concrete, 60+ yrs |

| Construction Speed | 7–15 Days (pre-cut kits) | 30–90 Days | 45–120 Days |

| Fire Resistance | A1, fully fireproof | C–D, combustible | A–B, partial |

| Thermal Efficiency | R28–R40, no thermal bridges | R10–R14, subject to settlement gaps | R12–R17, passive house retrofit possible |

| Maintenance Needs | Low—non-corrosive, repaint 20+ yrs | Medium—re-treatment every 5–7 yrs | Medium—potential for cracks |

| Customization | High (modular facades, 1000s of plans) | Medium | Low |

Top Metal Building Manufacturers & Certification

- Hongji Shunda Steel Structure (ISO 9001/14001, CE): Engineered Steel Metal Garage Kits

- Butler Manufacturing (ISO, FM Approved)

- Mueller Steel Buildings (ASTM, ICC Certified)

- BlueScope Steel (LEED, AS/NZS standards)

7. Customization Solutions - Modular, Tailored, Smart

Metal buildings for residential use are no longer limited to basic sheds! Whether seeking high-tech metal handrails residential for safety, luxury exteriors, or smart home integration, today’s pre-engineered steel kits support:

- Dimension Ranges: 3x4m to 50x60m+; clear internal spans up to 20+ meters.

- Finish Options: Stone-style wraps, wood grain coated panels, glass window clusters, high-quality powdercoat.

- CNC Customization: Any window/door layout cut directly in production, including high-precision fitting for metal handrails residential segments.

- Optional Packages: Solar/PV roofing, smart ventilation, green wall compatibility, garage doors, insulation upgrades (Rockwool/PU).

- Accessibility: All kits support ADA-compliant railings and barrier-free entry/exit as per ANSI-2009/ISO 21542.

8. Application Scenarios & Real User Experience

Case Studies: Residential Metal Building Adoption in Action

Result: 38% lower energy bills

Testimonial: "No creaking, no leaks — and impressively fast to assemble!" (customer)

Result: CO2 emissions cut by 27% (compared to wood).

Result: Passive cooling; local council awarded green building points.

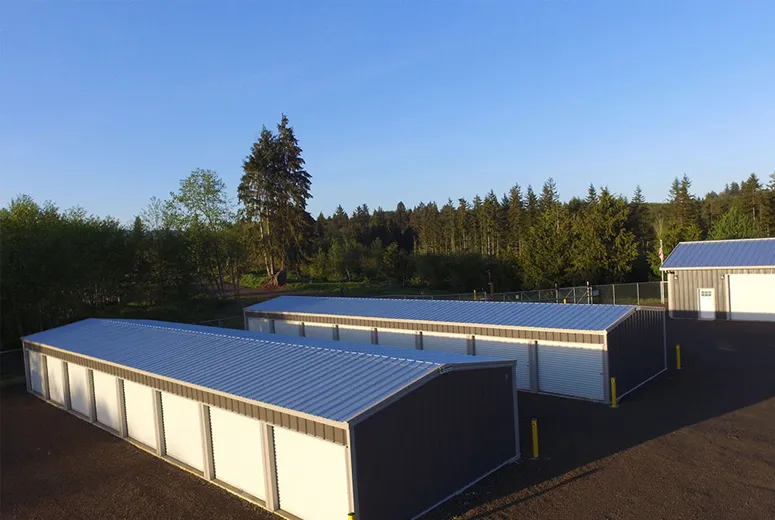

Project Gallery

9. Engineered Steel Metal Garage Kits: Quick Specification Table

| Item | Parameter | Value |

|---|---|---|

| Standard Size Range | Length × Width × Eave Height | 6–40m × 4–22m × 2.7–12m |

| Main Steel Grade | - | Q355B/S355JR, 304/316SS (optional) |

| Surface Protection | Coating | Hot dip galvanizing, PVDF |

| Frame Connection | Type | Pre-welded, bolt-together |

| Building Envelope | Wall and Roof Panel | Al-Zn alloy color steel / Sandwich |

| Insulation | Type | PU, Rockwool, EPS (customized) |

| Optional Packages | Available | Roller doors, double-glazed windows, metal handrails residential, solar roof |

| Color Selection | RAL Codes | Customized, 50+ available |

| Quality/Mgmt System | Certification | ISO9001 / ISO14001 / CE |

10. Professional FAQ: Metal Residential Building Terminology

- Q1: What distinguishes Q355B/S355JR steel in residential applications?

- These are high-strength structural steels. Q355B (Chinese GB/T) and S355JR (European EN10025) deliver 355MPa yield for optimal balance of strength, ductility, and weldability.

- Q2: How are metal handrails residential constructed for safety?

- Handrails use 304/316 stainless steel (anti-rust), formed by extrusion or TIG welding. Modular systems comply with ISO 3506 & ANSI A117.1 for barrier-free safety and strength.

- Q3: What does PVDF coating mean?

- Polyvinylidene fluoride (PVDF) offers premium UV, corrosion, and fade resistance. It's tested per ISO 9227 (salt spray) and outlasts regular polyester finishes.

- Q4: What is a sandwich panel system?

- Sandwich panels combine steel facings with an insulation core (PU, rockwool, or EPS), enhancing thermal performance and rigidity—common in metal buildings for residential use.

- Q5: How is fire resistance certified?

- Panels and steel are rated via EN 13501 (Euroclass), aiming for A1–A2 (non-combustible). US codes reference ASTM E119 time/temperature curves for certification.

- Q6: What is ISO 9001 and why is it critical?

- ISO 9001 is the international standard for quality management systems. It ensures every production/run of metal residential homes maintains traceable, consistent quality.

- Q7: Are these structures suitable for high corrosion environments?

- Yes! Hot-dip galvanizing, stainless steel elements, and PVDF coatings all yield exceptional resistance in petrochemical, water treatment, and ocean-front residential projects.

Delivery Time & Warranty

- Delivery Cycle: 10–30 days typical from design confirmation (size dependent, ex-works basis, includes cutting, assembly, and surface treatment).

- Warranty: 15–30 years on structure, 20 years on coatings, 3+ years on moving parts (e.g., doors).

- After Sales: Online/phone support, remote site advice, installation guides, and annual inspection checklists.

- Certifications: Full ISO9001 / 14001, CE, ANSI mark on all engineered steel metal garage kits.

Get a Free Custom Quotation for Your Metal Building

Click here for immediate consulting, or download full specs & samples.

11. References & Further Reading

- Metal Construction News: Metal Buildings in Residential Applications

- Journal of Constructional Steel Research: Technical advances in structural steel in housing

- International Code Council: IBC Standards for Metal Structures

- Steel Framing Alliance: Best Practices in Metal Residential Framing

-

The Rise of Prefabricated Metal Structures in Modern Industry

NewsJul.28,2025

-

The Landscape of Prefabricated Metal Building Solutions

NewsJul.28,2025

-

Analyzing Costs and Pricing Dynamics in Prefabricated Steel and Metal Buildings

NewsJul.28,2025

-

Advance Industrial Infrastructure with Prefabricated Steel Solutions

NewsJul.28,2025

-

Advancing Industrial Infrastructure with Prefabricated Metal Warehousing Solutions

NewsJul.28,2025

-

Advancing Industrial and Commercial Spaces with Prefabricated Steel Solutions

NewsJul.28,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.