- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 30, 2025 05:00 Back to list

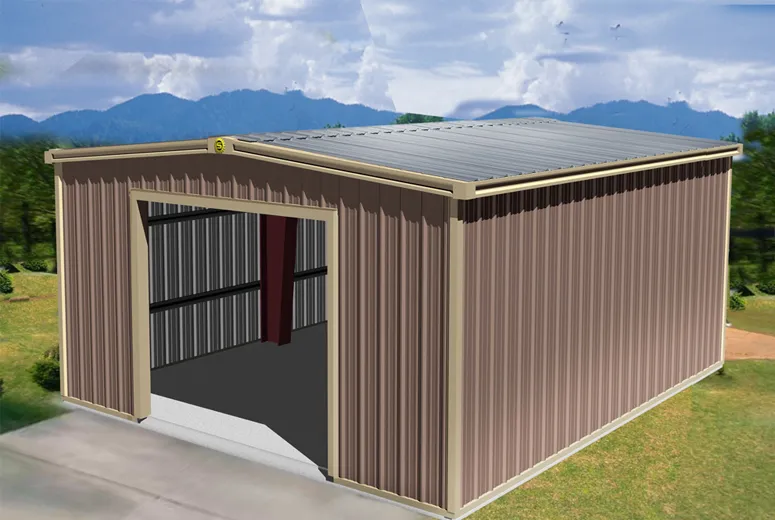

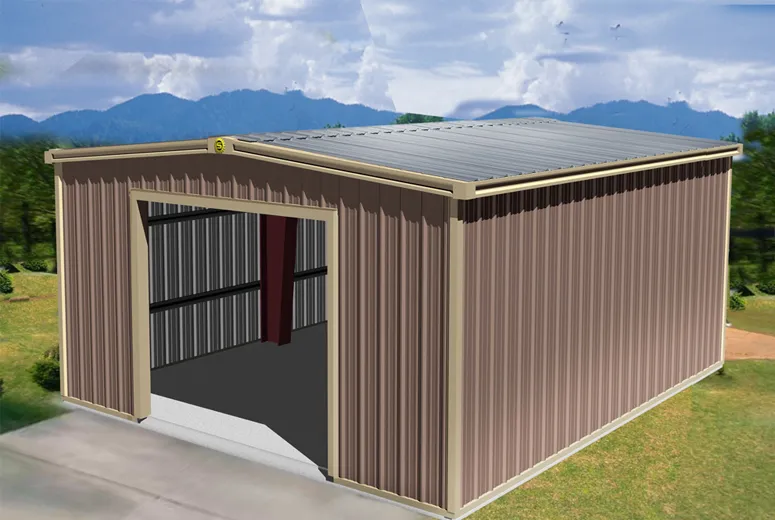

The demand for metal garage kits and related products such as metal building kit and metal warehouse kits continues to rise, fueled by the rapid growth of e-commerce logistics, industrial upgrades, and individual customization needs. Their robust construction, modular flexibility, and cost efficiency have made them a preferred choice across industries—ranging from petrochemicals to warehousing and residential storage.

1. Metal Garage Kits Industry Trends in 2024

- Market Expansion: The global market for metal garage kits is projected to reach USD 9.7 billion by 2027 (Grand View Research), boosted by increasing investments in infrastructure, logistics, and green building technologies.

- Technology Integration: Adoption of smart fabrication (CNC, laser cutting), advanced coatings, and sustainability standards (ISO 14001, EN 1090-2) is influencing product development as well as certification requirements.

- Customization Boom: Customers demand tailored metal garage kits for diverse applications—warehouse expansion, farm machinery storage, automotive workshops, and industrial logistics.

- Resilience and Lifespan: Enhanced standards for wind/snow load, anti-corrosion, and fire-resistance drive R&D and purchasing decisions.

Key Technical Specifications: Market Comparison Table

| Specification | Durable And Customizable Steel Metal Garage Kit | Standard Metal Garage Kit | Metal Warehouse Kit |

|---|---|---|---|

| Steel Grade | Q355B / ASTM A36 (Hot-dip galvanized) | Q235 / AISI 1018 | Q345 / ASTM A992 |

| Panel Thickness | 0.4-0.8mm (roof/wall), 1.0-2.5mm (main frame) | 0.3-0.6mm / 1.2mm | 0.5-0.9mm / 2.0mm |

| Coating Standard | Z275 (EN 10346, ISO 1461), PVDF/PE Paint | Z200, Regular Paint | Z275, Powder Coating |

| Wind Resistance | ≥ 150 km/h (EN 1991) | 120 km/h | 145 km/h |

| Corrosion Protection | Hot-dip galvanized, optional marine-grade | Electro-galvanized | Hot-dip galvanized |

| Design Life | ≥ 50 years | ~25 years | 35-40 years |

| Certification | ISO 9001, EN1090-2, ANSI/AISC 360 | ISO 9001 | EN1090-2 |

| Fire Resistance | Class A (GB8624-2012, ASTM E119) | Class B | Class A/B |

| Standard Size Range | Span: 6-40m, Length: Variable, H: 2.5-15m | S: 3-20m, L: Variable, H: 2.5-7m | S: 9-50m, L: Variable, H: 3.5-15m |

2. Manufacturing Process of Metal Garage Kits

Key Highlights of Manufacturing:

- Material Quality: Only certified alloys (Q355B steel, ASTM A36) with hot-dip galvanization for maximum anti-corrosion and ductility.

- Process Control: Automated cutting/welding & real-time inspection reduce variability, as per ISO 9001 and EN 1090-2 standards.

- Coating: PVDF/PE top coat conforms to ISO 1461 for anti-rust and environmental resistance.

- Dimensional Tolerance: All profiles machined within ±1mm tolerance, verified by 3D CMM (Coordinate Measuring Machine).

- Traceability & Testing: Each batch undergoes NDT (Non-Destructive Testing), ultrasonic and mechanical strength tests with records traceable for 15 years.

- Certifications: Products are supplied under ISO, ANSI/AISC 360-16 and regional certifications (CE, EN 1090-2) as required.

3. Technical Index Visualization

Comparison of key technical indices of Durable and Customizable Steel Metal Garage Kits vs. Standard Kits:

4. Diverse Applications of Metal Garage Kits

- Industrial Warehousing: Large-span, column-free design provides maximum storage, easy vehicle access. Structure tested for 150km/h wind, extreme snow load (GB50009-2012).

- Petrochem & Utility Sector: Corrosion-resistant shell enables installation in oil/gas refineries and water treatment plants—with special paint systems up to C5-M (ISO 12944) for coastal/high-sulphur environments.

- Automotive Workshops: Pre-designed bays for lifts, tool installation; 100% modular/expandable as business grows.

- Agricultural Machinery Storage: Custom spans house large combines, with optional insulation, fire-exit doors and ventilation modules.

- Retail & e-Commerce Logistics: Fast-build, scalable spaces for package handling—typically installed in 10-14 days for 500m² modules.

- Military & Special Use: Highly secure, rapidly deployable designs for equipment yards, emergency response, and UN relief missions.

Featured Application Case

—Logistics Director, SAP-Partnered European Fulfillment Hub

Cooperation & Certification

- Served over 320 custom projects in 25+ countries (Europe, NA, MENA, SEA, South America).

- Partners include SINOPEC, ABB, Siemens Logistics, Linde, Karcher.

- All products supplied with full traceability certificates, mill test reports, and 3rd-party QA as per ISO/EN1090-2 and ANSI/AISC 360 standard.

- Decades-long average service: Installations surviving >30 years in coastal, humid, and desert environments.

5. Custom Metal Garage Kits Solution Process

- Requirement Analysis: Free expert consulting—define usage, site dimensions, wind/snow/waterproof needs.

- Preliminary Design: 3D structural BIM proposal using Tekla structures, full CAD documentation.

- Quotation: Transparent bill-of-materials and ISO/ANSI-compliant costs breakdown.

- Factory Sampling: Optional sample module for dimension/compatibility check prior to full production.

- Production & Inspection: Real-time customer video updates, batch-by-batch photographic QA records.

- Packing & Logistics: Green packaging, anti-moisture wrap, steel palletizing, tracked door-to-door delivery.

- Onsite Guide/Remote Support: Full install guidebook, technical drawings, video/VR support. Local install team dispatch optional for key markets.

Delivery Cycle & Support

- Typical Leadtime: 500m² standard kit: 15-20 working days EXW.

- Custom Project: 800-1500m²: 20-35 working days (peak), larger projects 40-70 days with phased delivery.

- After-Sales Service: 7x24h multilingual support, 1-hour response window. Free defective part replacement within warranty.

- Warranty: 15-year anti-corrosion guarantee, 25-year structural warranty (material loss ≥ 20% thickness).

- Support Materials: All clients receive digital/print install guides, 3D animation videos, and online/onsite training as needed.

FAQ: Metal Garage Kits Industry Standards & Technology

A: The primary steel grades are Q355B or ASTM A36, chosen for their high tensile strength (>470MPa), excellent ductility, and superior weldability. Hot-dip galvanizing ensures rust protection and compliance with ISO 1461 and EN1090-2 standards.

A: Roof/wall sheets typically range from 0.4-0.8mm, allowing for a lightweight yet weather-resistant structure. Main columns and beams can be up to 2.5mm-8mm thick for heavy-duty applications.

A: Loads are calculated per EN 1991 (Eurocode 1) and local codes (e.g., ASCE 07). Our kits withstand winds up to 150km/h and snow ≥1.5kN/m², validated by FEA simulation.

A: Coating is applied per ISO 1461, EN10346, and ANSI/SSPC-PA1. Zinc layer (Z275) or marine-grade coatings offer protection even in coastal/chemical-industry use.

A: All units utilize Bolt-on modularity—expansion or reconfiguration is possible even post-installation, without hot works. BIM design enables 100% virtual pre-check before site delivery.

A: Factory-prefabricated kits enable rapid assembly: 4-7 days by an experienced 5-person team, using only basic tools/lift equipment. No welding/special machinery needed onsite.

A: We provide 15 years corrosion protection and 25 years structural guarantee. All support is multilingual, 7x24h, direct from engineering and after-sales specialists with >10 years of field experience.

Product Specification Table: Durable And Customizable Steel Metal Garage Kits

| Attribute | Specification/Option |

|---|---|

| Material | Q355B (EN10025-2), ASTM A36/A992, Hot-dip galvanized |

| Frame System | Portal frame, lattice / H-beam, modular bolts (Grade 10.9Zinc) |

| Surface Finish | Zinc coating ≥ 275g/m², PVDF/PE paint; marine paint optional |

| Roof & Wall Sheet | Corrugated PPGI / Sandwich panel (EPS/Rockwool/PU), optional insulation |

| Structural Span | 6-40m (custom) |

| Column Height | 2.5-15m (custom) |

| Design Load | Wind: 0.5-2.5kN/m², Snow: 0.2-2.0kN/m², Seismic 6-8° |

| Access | Roll-up doors (manual/electric), side/personal doors; windows, skylights |

| Fire Resistance | Class A, smoke/toxicity tested as per GB8624-2012, UL/ASTM |

| Certification | ISO 9001:2015, EN 1090-1/2, ANSI/AISC, CE Marking (optional) |

| Lifespan | ≥ 50 years (inland standard), ≥ 35 years (marine/chemical use) |

Authoritativeness & Industry Validation

- Years of Experience: >15 years in steel structure manufacturing, 400+ international shipments to over 28 countries.

- Industry Affiliations: Member of China Steel Structure Association (CSSA), European Construction Steelwork Association (ECSA), and AISC international procurement partners.

- 3rd-party Testing: All products tested per SGS, Bureau Veritas, and TÜV Rheinland upon request.

- Regulatory Compliance: Strict conformance to ISO 9001:2015, EN1090, ANSI/AISC 360-16, ASCE/SEI 7-16.

- Major Projects Referenced: Industrial park warehouses (Germany), Petrochemical refining facility (Kuwait), E-commerce distribution (Brazil), and more.

- Testimonials: Consistent 98% customer satisfaction rate in technical engineering support and on-time delivery (2023 post-sale surveys).

References & Further Reading

- Grand View Research, "Metal Building Market Size, Growth & Trends Report 2023-2030"

- "Analysis and Engineering Practice of Metal Structure Modular Warehouses", Steelhome Forum, 2022

- Estructura Magazine, "Trends in Prefabricated Steel Buildings", 2023. Read Article

- American Institute of Steel Construction (AISC): "Engineering Journal"

- European Convention Constructional Steelwork, "Steelwork News & EU Guidelines"

-

The Rise of Prefabricated Metal Structures in Modern Industry

NewsJul.28,2025

-

The Landscape of Prefabricated Metal Building Solutions

NewsJul.28,2025

-

Analyzing Costs and Pricing Dynamics in Prefabricated Steel and Metal Buildings

NewsJul.28,2025

-

Advance Industrial Infrastructure with Prefabricated Steel Solutions

NewsJul.28,2025

-

Advancing Industrial Infrastructure with Prefabricated Metal Warehousing Solutions

NewsJul.28,2025

-

Advancing Industrial and Commercial Spaces with Prefabricated Steel Solutions

NewsJul.28,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.