Sep . 22, 2025 17:45 Back to list

Introduction to Airplane Hangar Metal Buildings

As the aviation industry continues to evolve, the demand for durable, efficient, and customizable hangar solutions has never been higher. Airplane Hangar Metal Buildings have emerged as a preferred choice for airports, private aviation facilities, and maintenance centers worldwide. These structures combine advanced engineering with modern design principles to meet the unique requirements of aircraft storage, maintenance, and operations. This article explores the key features, technical specifications, and applications of these metal buildings, while highlighting the expertise of Hebei Hongji Shunda Steel Structure Engineering Co., Ltd, a leading manufacturer in this field.

Figure 1: Modern steel structure hangar design

Key Features and Advantages

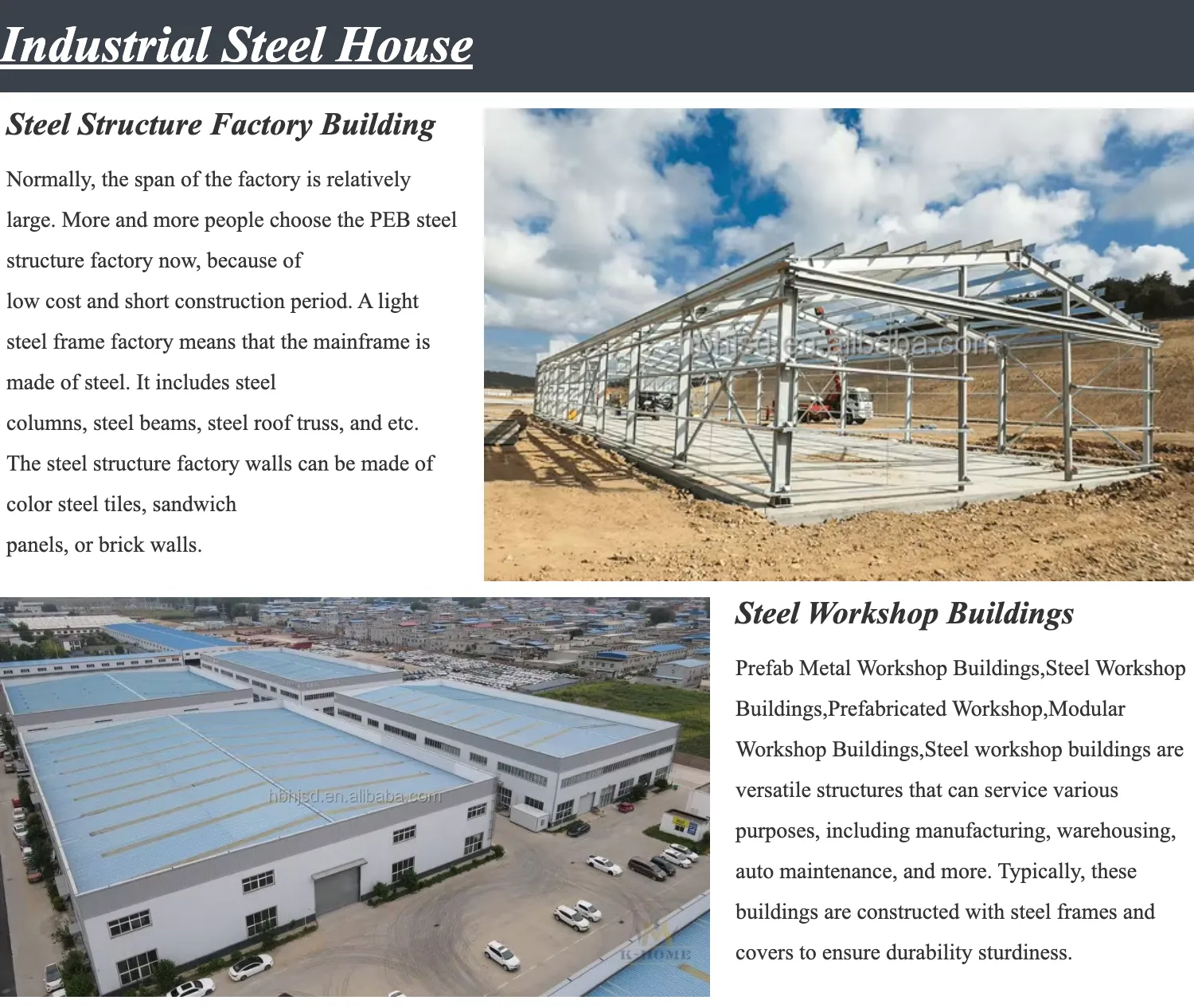

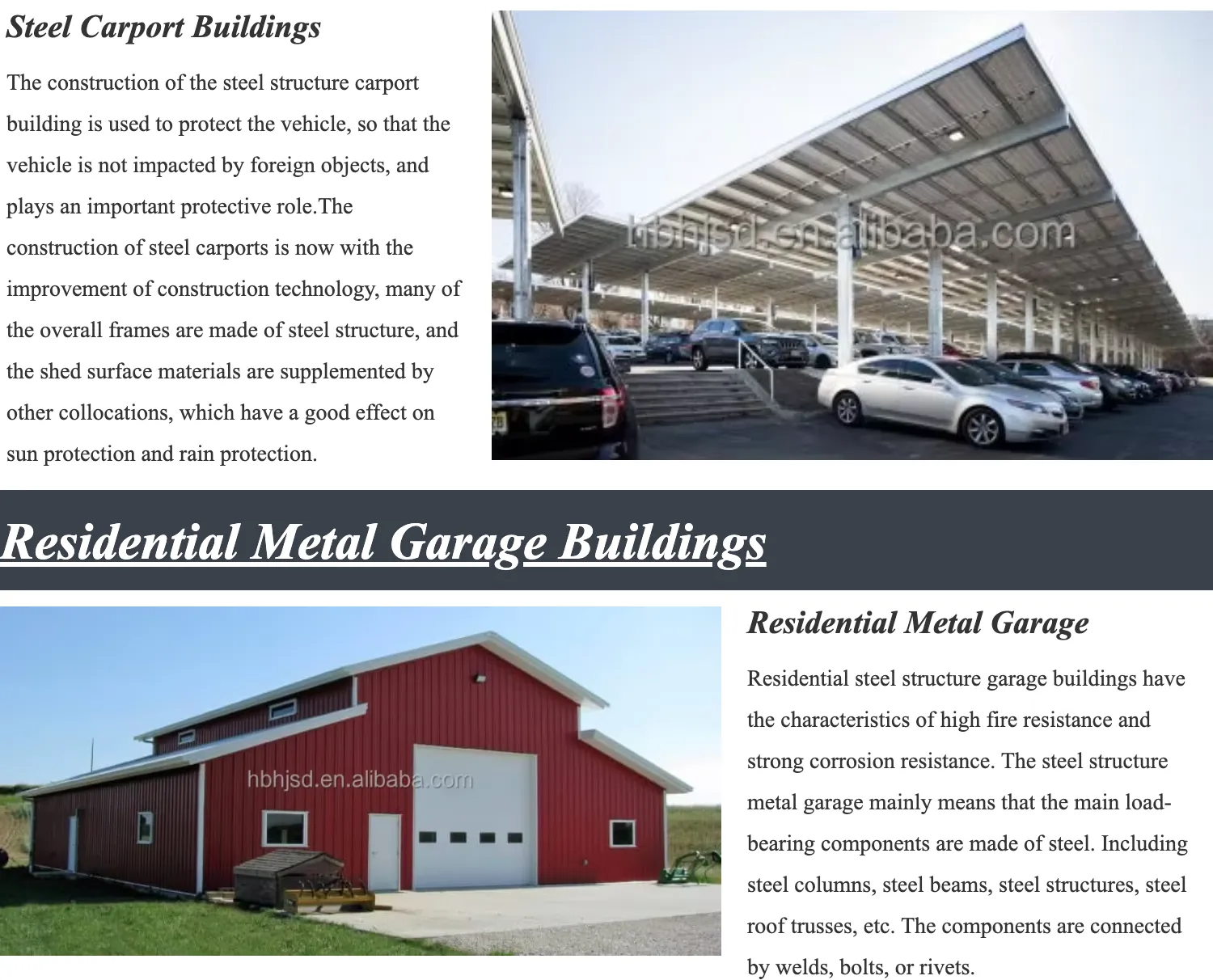

Steel hangar buildings offer a range of benefits that make them ideal for aviation applications. These structures are engineered to withstand harsh environmental conditions while providing exceptional durability and longevity. One of the primary advantages is their prefabricated construction, which significantly reduces on-site assembly time and labor costs. This modular approach allows for rapid deployment, making it an excellent solution for both new installations and expansion projects.

Figure 2: Spacious interior layout with overhead cranes

Another critical feature is the versatility of these buildings. They can be customized to accommodate a wide range of aircraft sizes, from small private planes to large commercial jets. The steel structure hangar designs include options for single corrugated steel sheet coverage, insulated roofs with single steel sheet walls, and other configurations to suit specific climate and functional requirements. This adaptability ensures that the structures can meet the unique needs of different aviation facilities.

Figure 3: Robust steel frame assembly

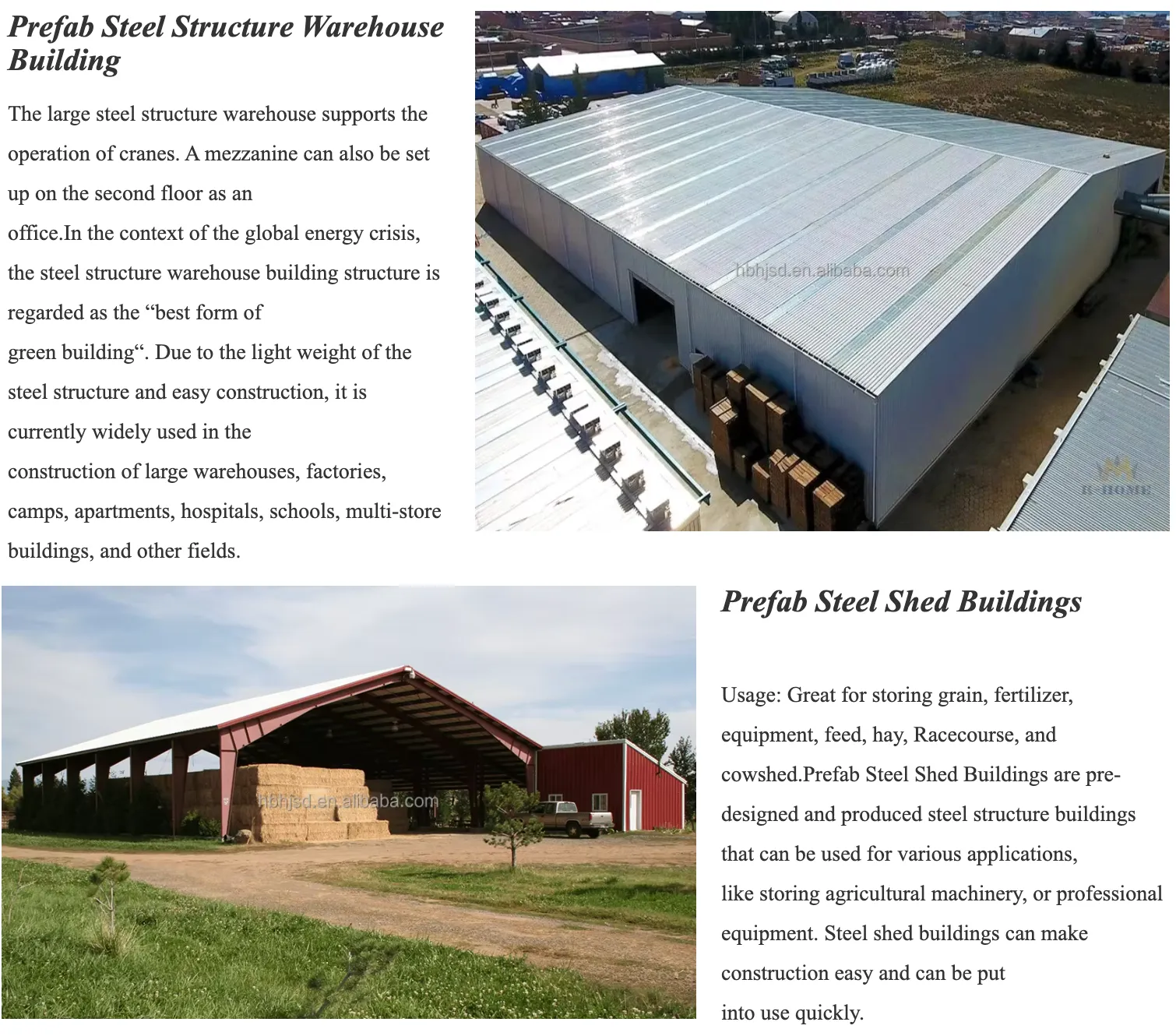

Additionally, these hangars are designed with safety in mind. The use of high-quality steel materials ensures structural integrity, while advanced engineering techniques enhance resistance to wind, snow, and seismic activity. The inclusion of large access gates, such as 18x4.5m and 18x5m options, facilitates easy movement of aircraft and equipment. For those seeking a more compact solution, smaller gate sizes like 14x3.5m are also available.

Technical Specifications

| Specification | Details |

|---|---|

| Material | High-strength steel alloy |

| Dimensions | Customizable (standard sizes: 20x30m, 20x50m, 16x36m) |

| Height | 4m, 5m, 6m (custom options available) |

| Coverage Options | Single corrugated steel sheet, insulated roof with single steel sheet wall, or single steel sheet only |

| Gate Sizes | 18x4.5m, 18x5m, 14x3.5m (customizable) |

| Wind Resistance | Designed for up to 120 km/h wind loads |

| Seismic Resistance | Compliant with international seismic standards |

Figure 4: Customizable size options for hangar buildings

Applications and Use Cases

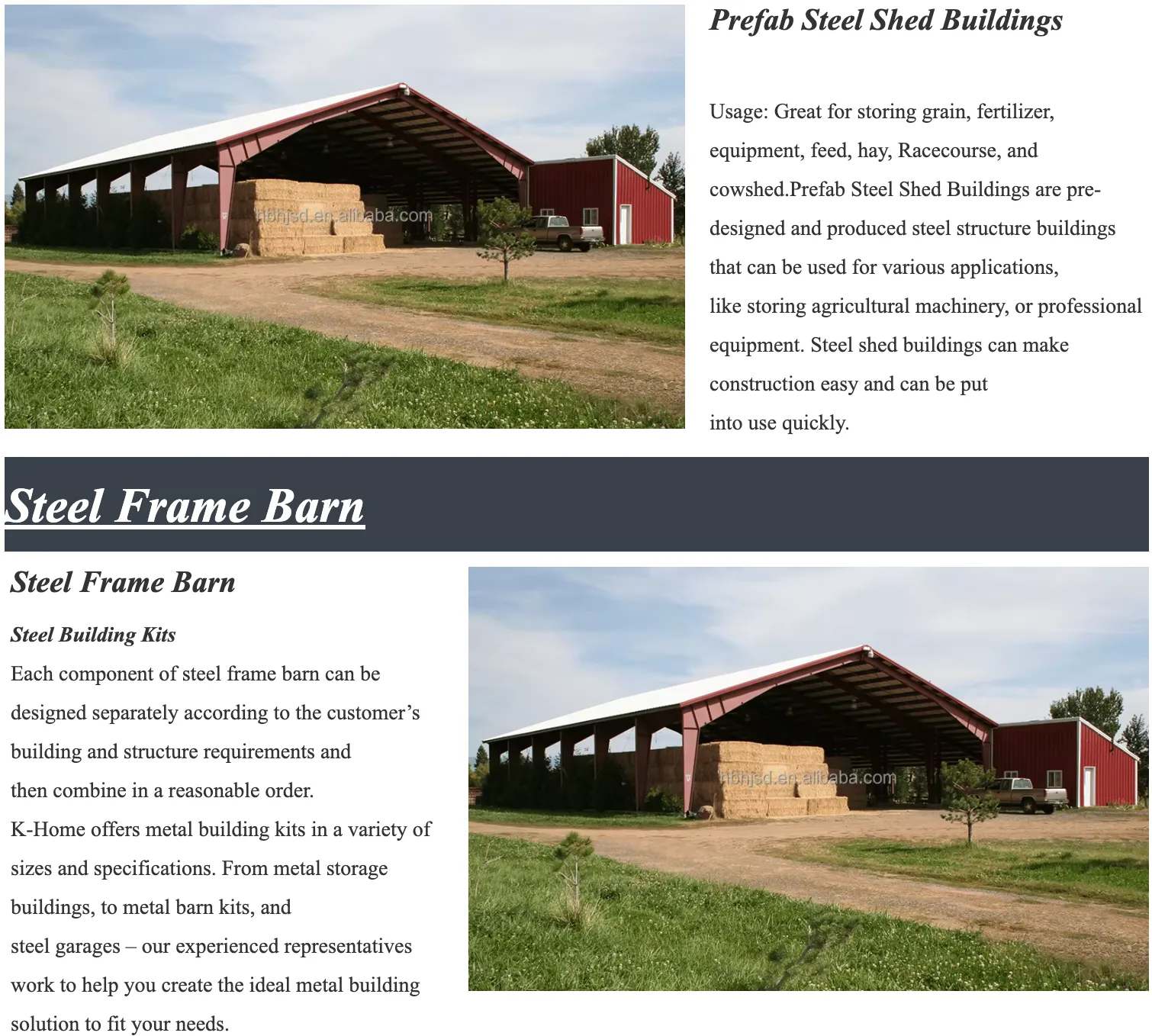

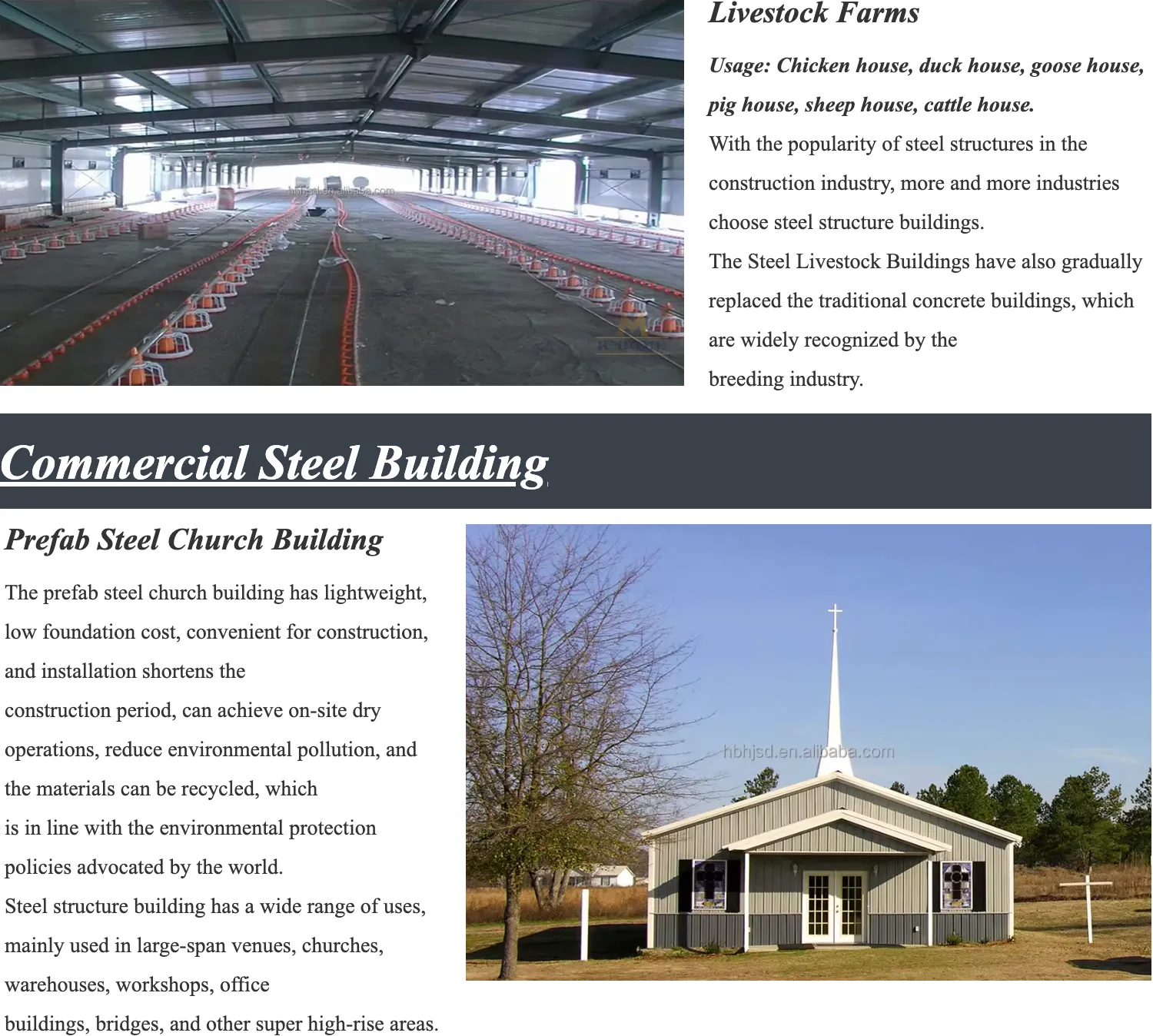

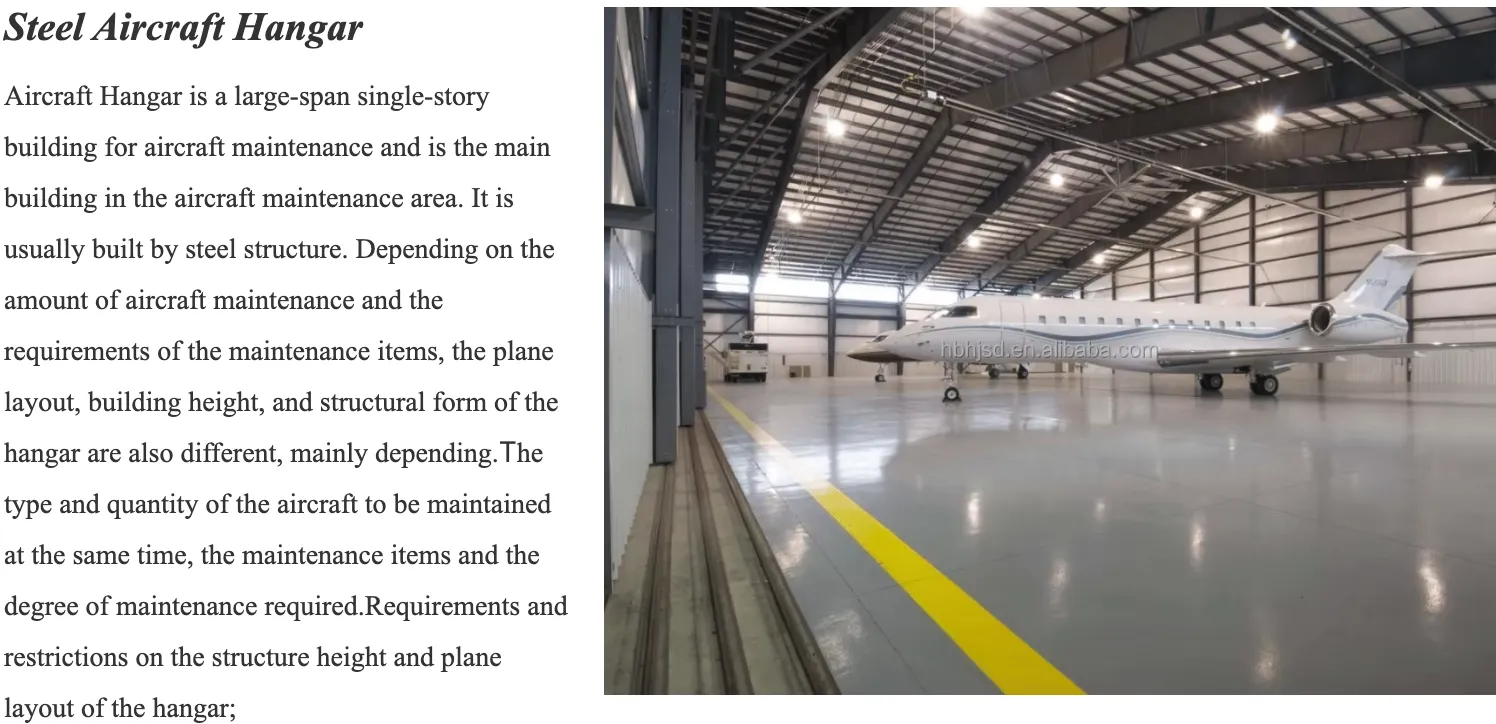

Airplane hangar metal buildings are utilized in a variety of aviation-related applications. Their primary function is to provide secure and protected storage for aircraft, safeguarding them from weather damage and unauthorized access. These structures are also essential for maintenance and repair operations, offering a controlled environment for technicians to work on aircraft systems.

Figure 5: Equipped maintenance bay with overhead cranes

For airports and airfields, these hangars can be integrated into larger infrastructure projects, providing additional capacity for aircraft storage and operations. Private aviation facilities also benefit from the flexibility and cost-effectiveness of steel hangar buildings, which can be tailored to accommodate specific aircraft models and operational needs. Furthermore, the structures are suitable for use in remote locations where traditional construction methods may be impractical.

Figure 6: Advanced crane systems for aircraft maintenance

Another notable application is in the defense sector, where secure and durable hangars are required for military aircraft storage and maintenance. The robust construction of these buildings ensures they can withstand extreme conditions, making them ideal for both civilian and military use.

Company Background and Expertise

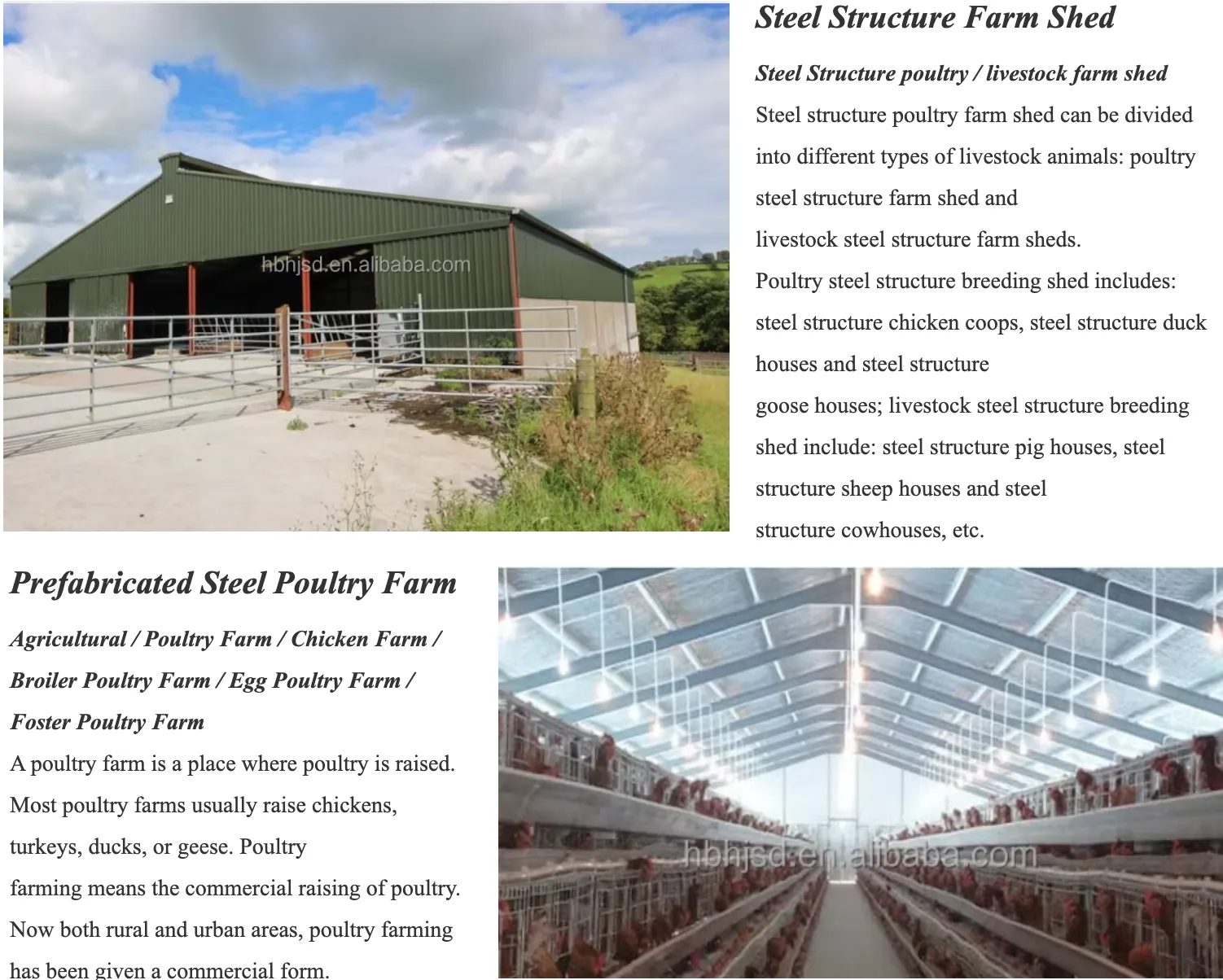

Hebei Hongji Shunda Steel Structure Engineering Co., Ltd has established itself as a leader in the design and manufacturing of steel structure buildings, including airplane hangar metal buildings. With years of experience in the industry, the company has developed a reputation for delivering high-quality, customized solutions that meet the rigorous demands of the aviation sector.

Figure 7: Hebei Hongji Shunda's manufacturing facilities

The company's commitment to innovation is evident in its use of advanced engineering software and state-of-the-art fabrication techniques. This ensures that every project is executed with precision, from the initial design phase to the final installation. Hebei Hongji Shunda also places a strong emphasis on sustainability, incorporating energy-efficient materials and practices into its manufacturing processes.

Customer satisfaction is a top priority for Hebei Hongji Shunda. The company offers comprehensive support throughout the project lifecycle, including consultation, design, and after-sales service. This holistic approach has enabled the company to build long-term relationships with clients across the globe, including major airports, aviation companies, and defense organizations.

Industry Standards and Compliance

As highlighted by the National Institute of Standards and Technology (NIST), the construction industry must adhere to strict safety and quality standards to ensure the reliability of infrastructure. Hebei Hongji Shunda's steel hangar buildings are designed in accordance with these principles, incorporating rigorous testing and quality control measures throughout the manufacturing process. The company's structures meet international standards for structural integrity, fire resistance, and environmental resilience, as outlined in NIST's guidelines for industrial construction.

According to NIST, "The integration of standardized materials and construction methods is critical for ensuring the longevity and safety of industrial structures. This is particularly important in sectors such as aviation, where the consequences of structural failure can be catastrophic" (NIST, 2023). Hebei Hongji Shunda's adherence to these standards underscores its commitment to excellence and customer safety.

Figure 8: Quality assurance and testing procedures

Conclusion

Airplane hangar metal buildings represent a significant advancement in aviation infrastructure, offering a combination of durability, flexibility, and cost-effectiveness. With their ability to withstand extreme conditions and adapt to diverse operational needs, these structures have become an essential component of modern aviation facilities. Hebei Hongji Shunda Steel Structure Engineering Co., Ltd has demonstrated its expertise in this field, delivering high-quality solutions that meet the highest industry standards.

For those seeking reliable and innovative hangar solutions, Hebei Hongji Shunda provides a comprehensive range of products and services tailored to the unique requirements of the aviation industry. Whether for commercial airports, private aviation, or defense applications, their steel structure hangars offer a dependable and efficient solution for aircraft storage and maintenance.

-

Bolted Connections in Steel Frame Warehouse

NewsNov.17,2025

-

Hay Storage in Farm Metal Buildings

NewsNov.17,2025

-

Advantages of a Steel Portal Frame Shed

NewsNov.17,2025

-

The Erection Process of a Steel Building Hangar

NewsNov.17,2025

-

Energy Efficiency of Steel Dome Garage Kits

NewsNov.17,2025

-

Fire Resistance of Kit Metal Garages

NewsNov.17,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.