Sep . 28, 2025 06:00 Back to list

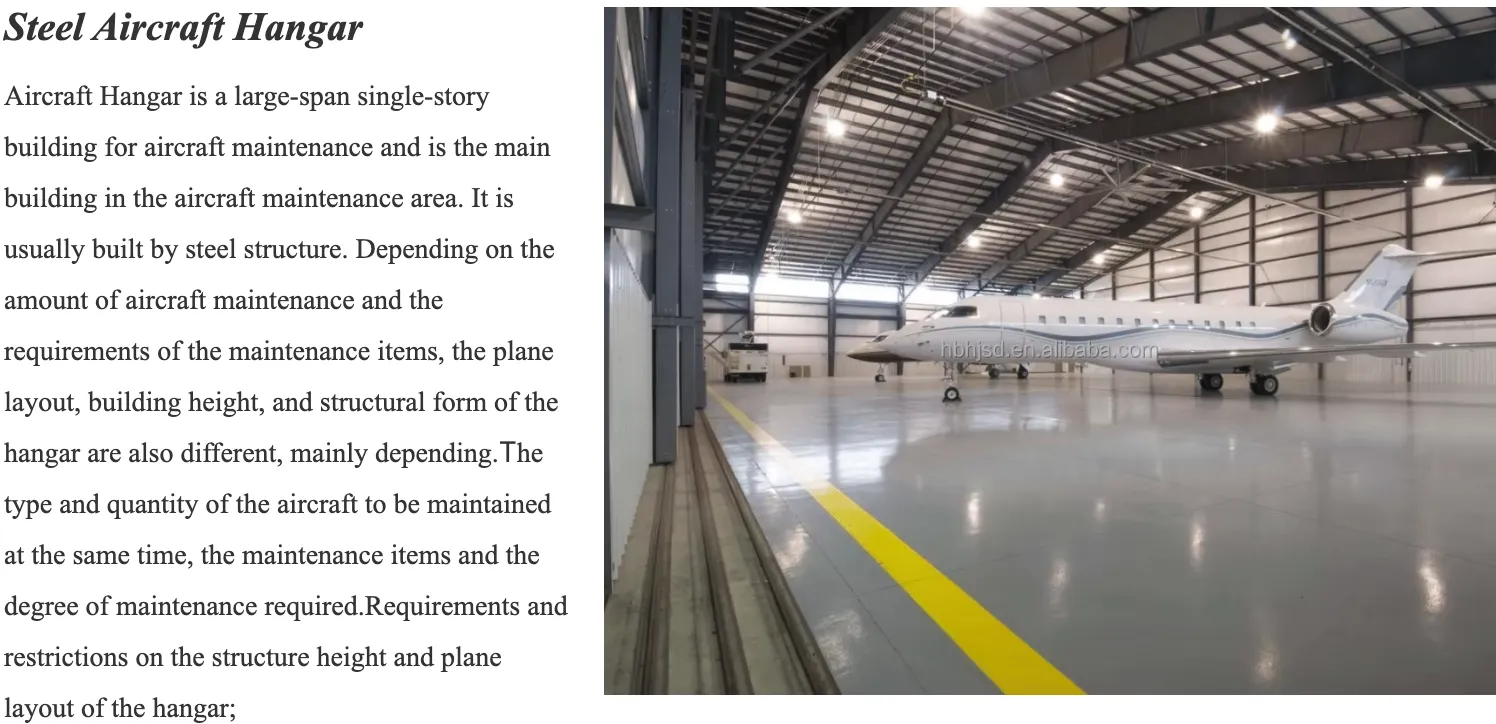

Airplane hangar metal buildings have become a cornerstone of modern aviation infrastructure, offering a blend of structural integrity, cost-effectiveness, and adaptability. Designed for both commercial and private aviation, these steel structure hangars are engineered to meet the rigorous demands of aircraft storage, maintenance, and operations. This article explores the features, advantages, technical specifications, and applications of steel hangar buildings, while also highlighting the expertise of Hebei Hongji Shunda Steel Structure Engineering Co., Ltd., a leading provider in this domain.

Key Features of Airplane Hangar Metal Buildings

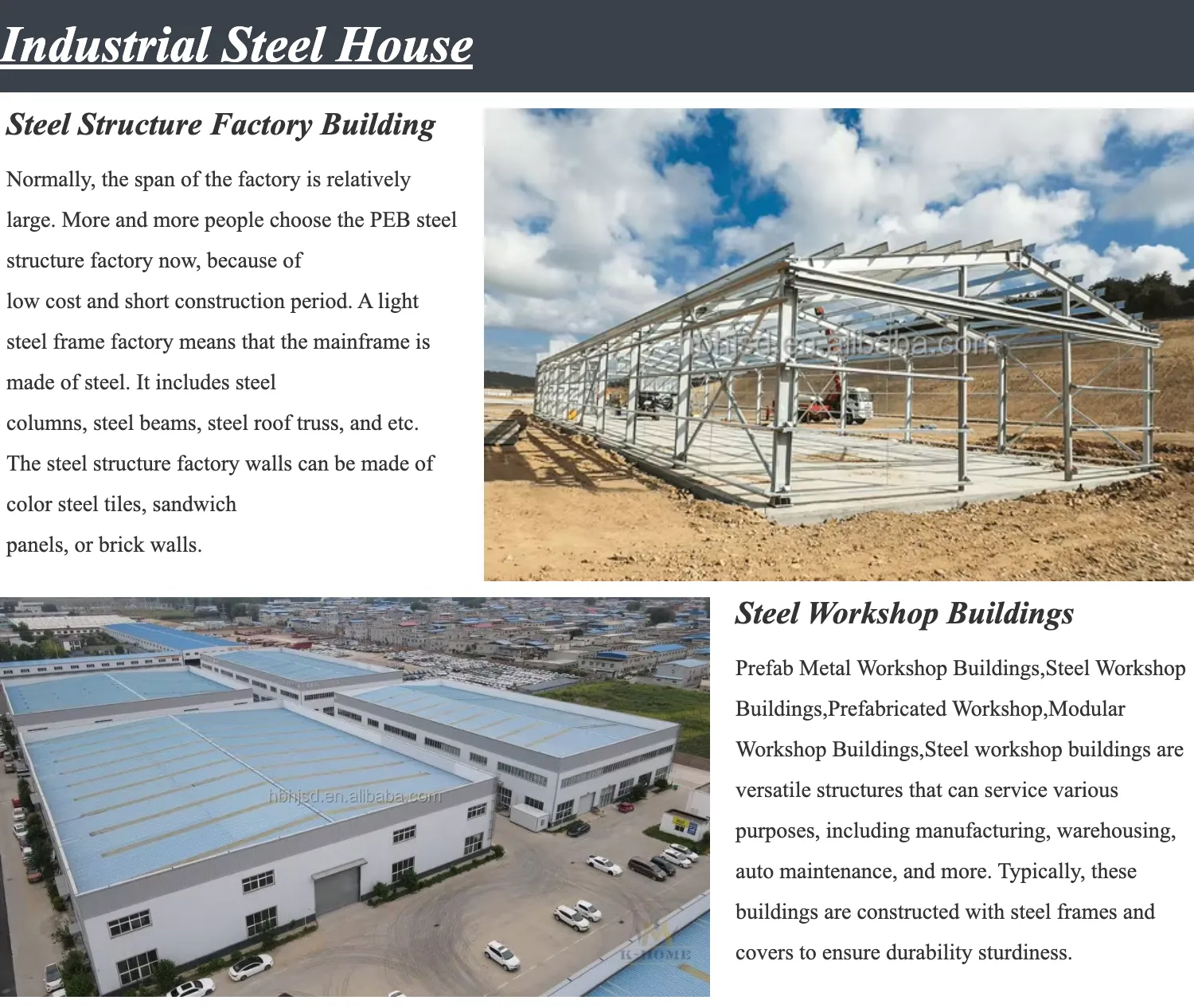

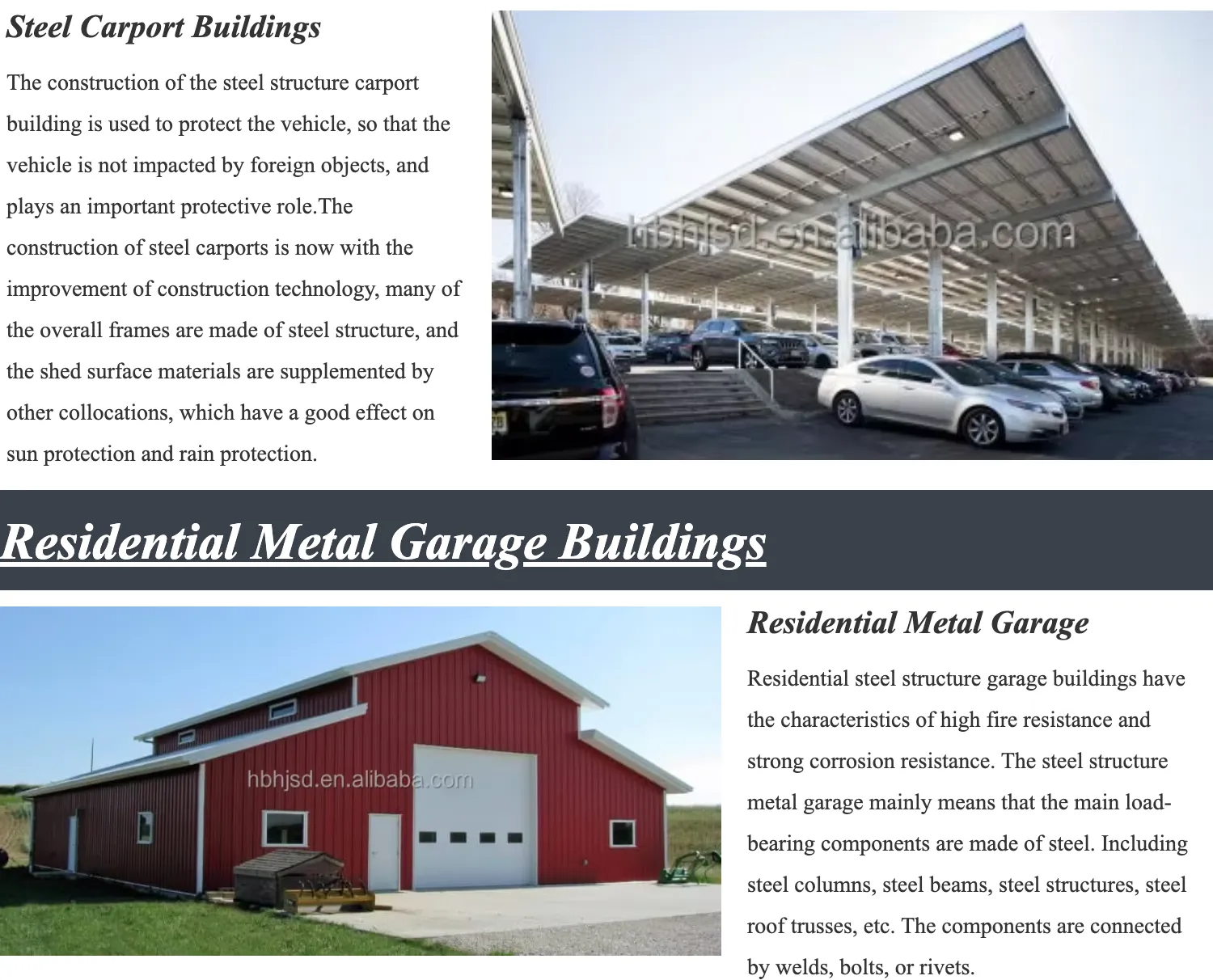

Steel hangar buildings are characterized by their modular design, high durability, and customizable configurations. These structures are typically constructed using prefabricated steel components, which are assembled on-site to minimize construction time and costs. The steel structure hangar is designed to withstand extreme weather conditions, including high winds, heavy snow, and seismic activity, making it an ideal choice for regions with challenging climates.

One of the standout features of these hangars is their versatile coverage options. The popular sizes include 20x30m, 20x50m, and 16x36m, with popular heights of 5m, 6m, and 4m. This flexibility allows customers to select a configuration that best suits their operational needs. The coverage options range from single corrugated steel sheets to insulated roofs with single steel sheet walls, ensuring optimal thermal performance and energy efficiency.

Gate sizes are also tailored to accommodate different aircraft types. Standard gate dimensions include 18x4.5m, 18x5m, and 14x3.5m, enabling seamless access for large aircraft such as commercial planes and military jets. The prefabricated hangars are further enhanced with robust steel frames and corrosion-resistant coatings, ensuring long-term durability and minimal maintenance requirements.

Advantages of Steel Hangar Buildings

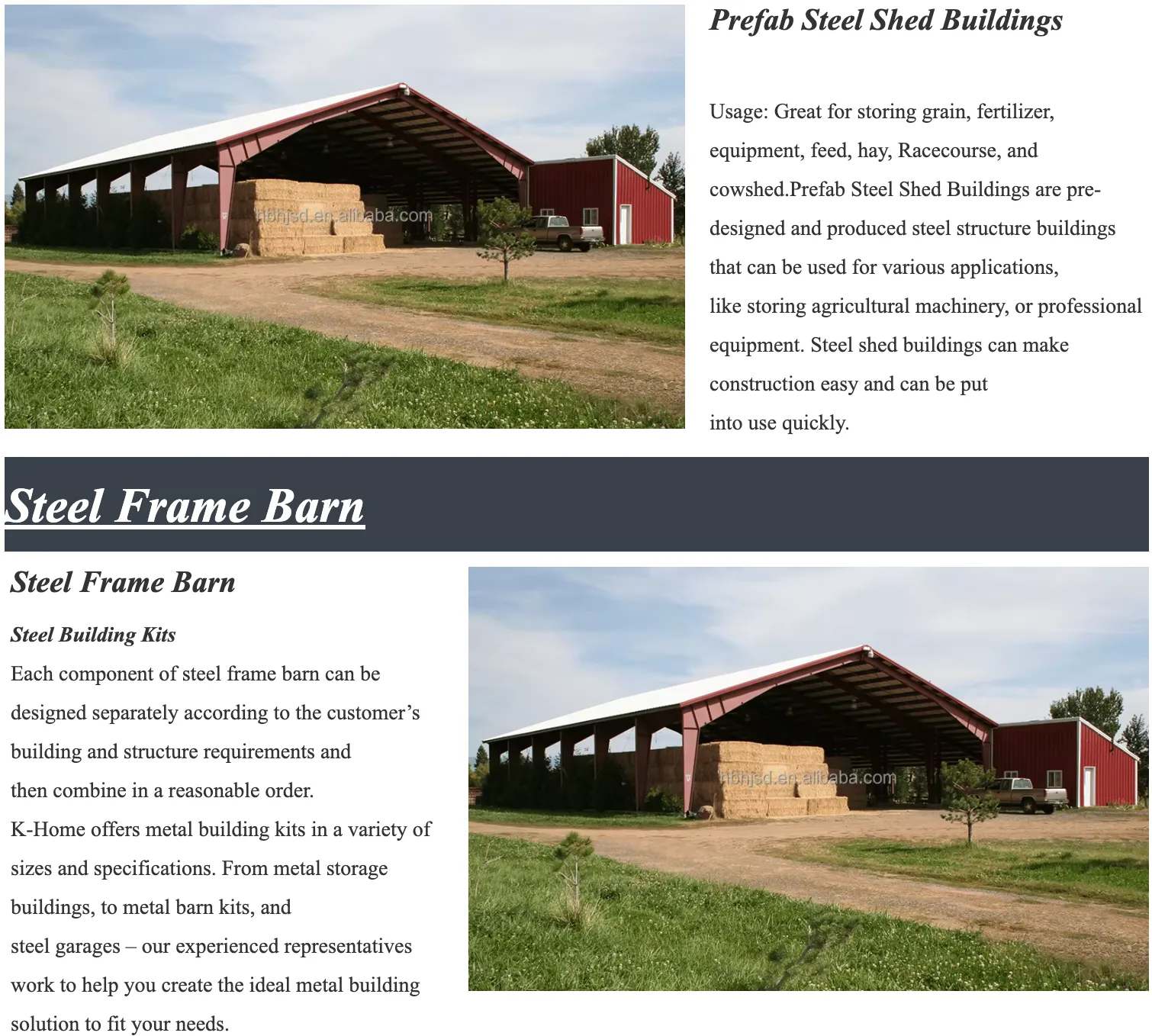

Steel hangar buildings offer a multitude of benefits that make them a preferred choice for aviation facilities. One of the primary advantages is their cost-effectiveness. Compared to traditional construction methods, steel structure hangars require less time and labor to build, significantly reducing overall project costs. Additionally, the modular design allows for easy expansion or reconfiguration, providing long-term scalability.

Another key benefit is the environmental sustainability of steel construction. Steel hangar buildings are made from recyclable materials, and their energy-efficient insulation reduces heating and cooling costs. This aligns with global efforts to minimize the carbon footprint of infrastructure projects. Furthermore, the lightweight yet strong steel framework ensures that the structure can support heavy loads without compromising safety.

Prefabricated hangars also excel in speed of construction. With pre-engineered components manufactured off-site, the assembly process can be completed in a fraction of the time required for conventional buildings. This is particularly advantageous for airports and aviation companies that need to minimize downtime during construction.

Technical Specifications of Airplane Hangar Metal Buildings

The technical specifications of steel hangar buildings are designed to meet the highest industry standards. Below is a detailed overview of the key parameters:

| Parameter | Details |

|---|---|

| Material | High-strength steel (Q235/Q345 grades) |

| Dimensions | Customizable (standard sizes: 20x30m, 20x50m, 16x36m) |

| Height | 4m, 5m, 6m (adjustable based on requirements) |

| Coverage Options | Single corrugated steel sheet, insulated roof with single steel sheet wall, or single steel sheet only |

| Gate Sizes | 18x4.5m, 18x5m, 14x3.5m (customizable) |

| Wind Load Capacity | Up to 1.5 kN/m² (meets international standards) |

| Snow Load Capacity | Up to 1.0 kN/m² (adjustable for different regions) |

| Corrosion Resistance | Galvanized steel with anti-rust coatings |

These specifications ensure that airplane hangar metal buildings are not only durable but also adaptable to diverse environmental and operational conditions. The use of high-strength steel and advanced manufacturing techniques guarantees structural stability and longevity.

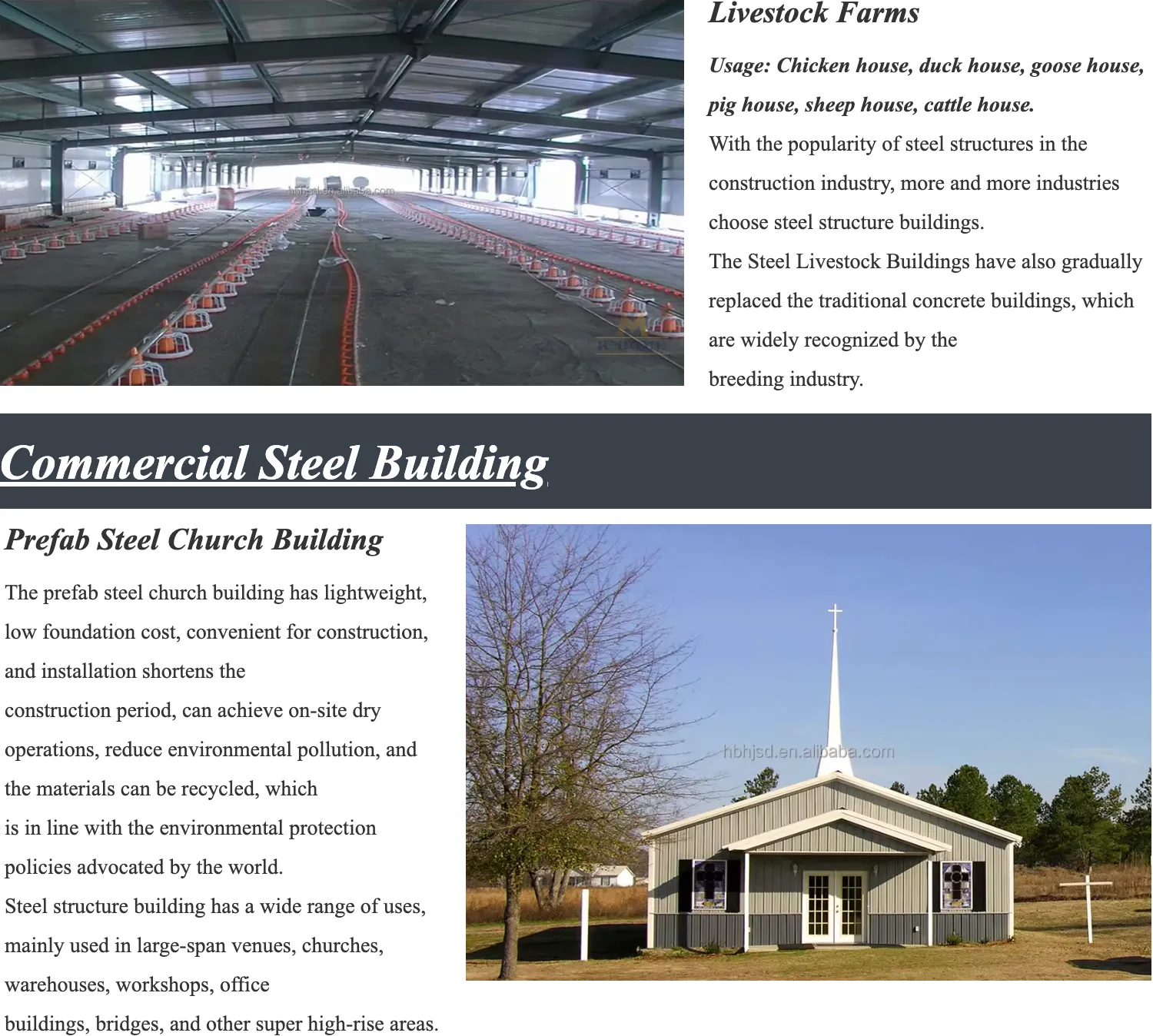

Applications of Steel Hangar Buildings

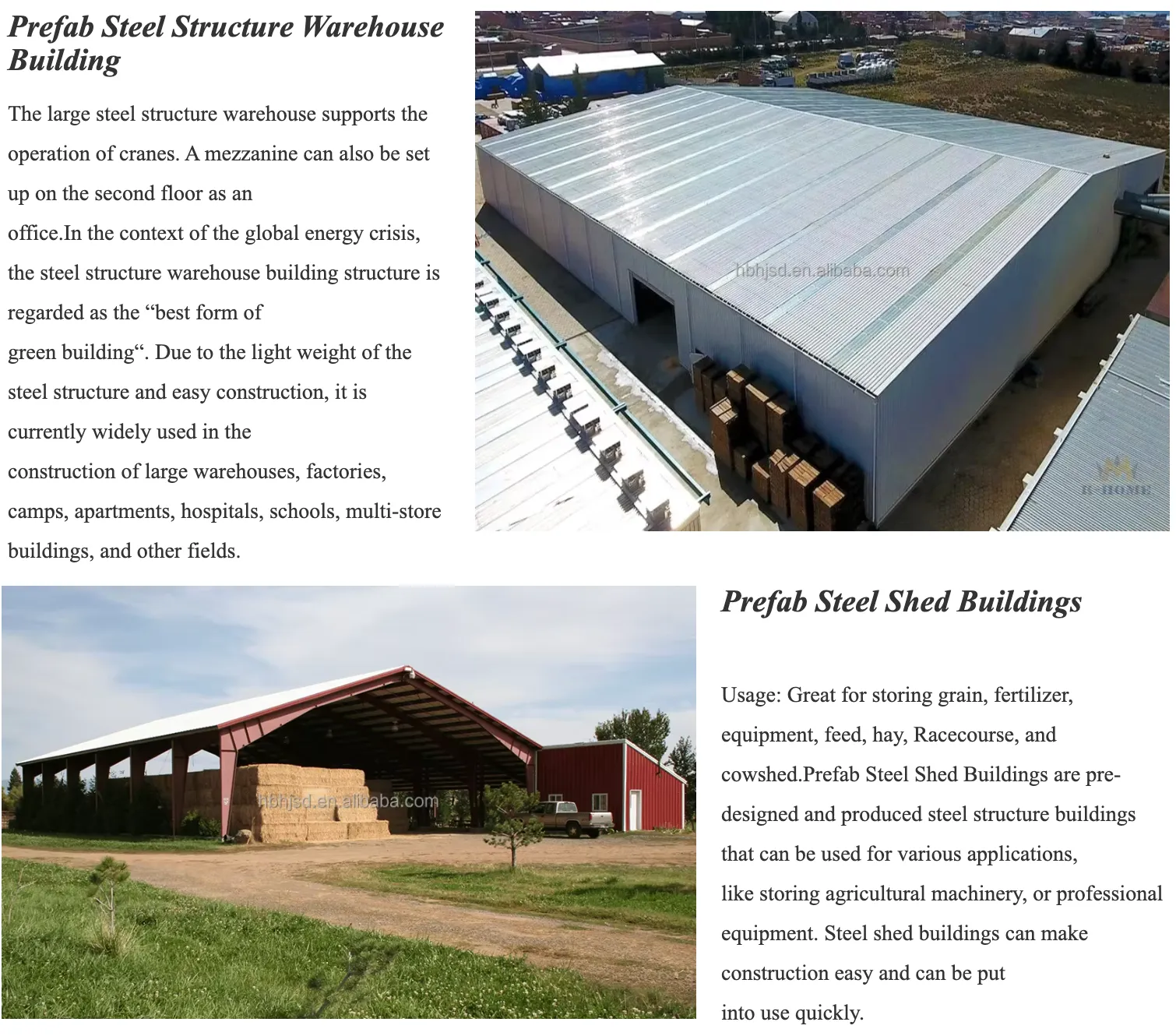

Steel hangar buildings are widely used in various aviation and industrial sectors. Their modular design and scalability make them suitable for a range of applications, including:

- Commercial Airports: Storing and maintaining large aircraft such as Boeing 737 and Airbus A320.

- Military Bases: Providing secure and durable facilities for fighter jets, helicopters, and other military aircraft.

- Private Aviation: Offering customized hangars for private jets and small aircraft.

- Industrial Facilities: Serving as warehouses, workshops, or storage units for heavy machinery and equipment.

The flexibility of steel hangar buildings also makes them ideal for temporary or emergency use, such as disaster relief operations or mobile aviation support units. Their easy assembly and disassembly allow for quick deployment in remote or challenging locations.

Company Background: Hebei Hongji Shunda Steel Structure Engineering Co., Ltd.

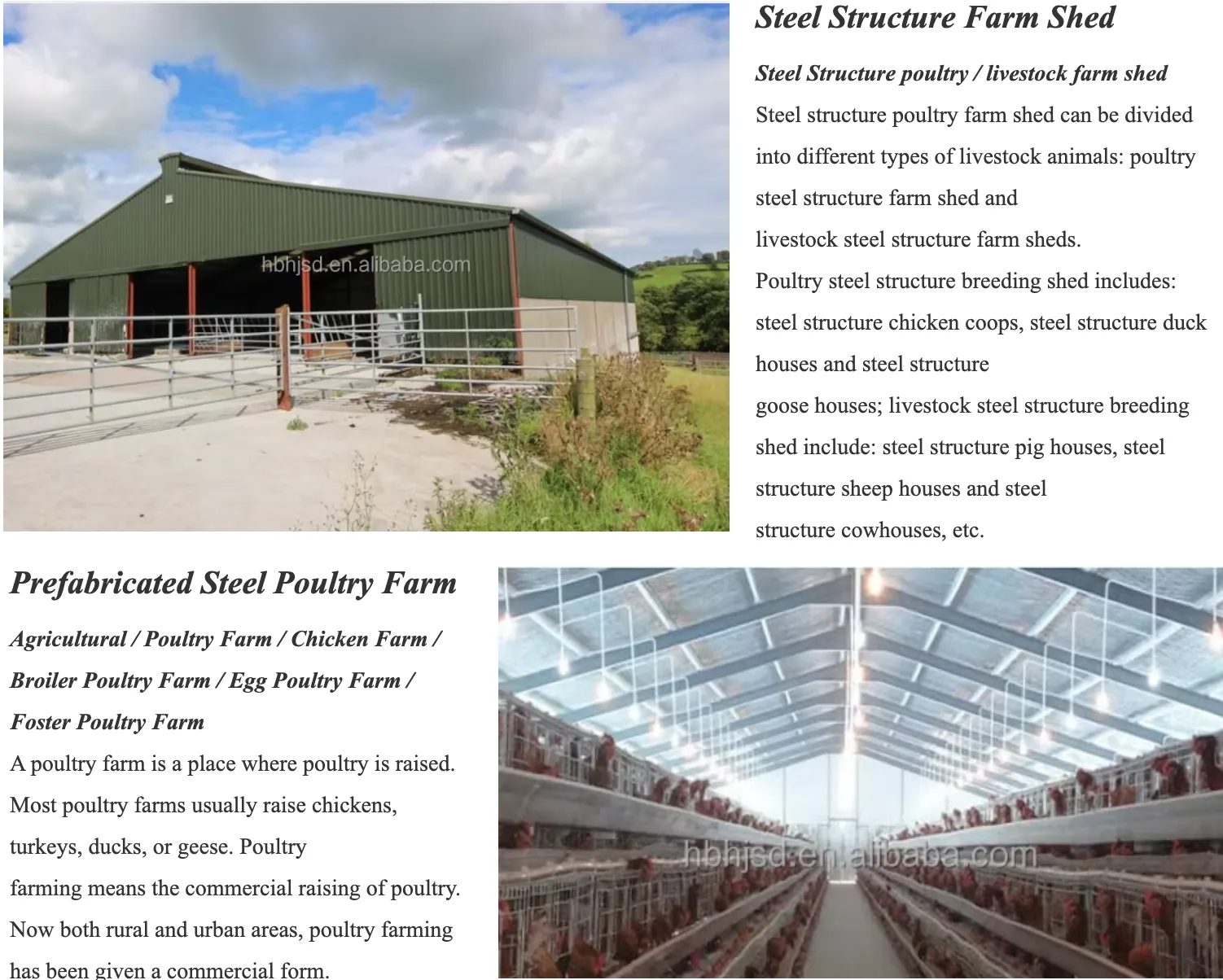

Hebei Hongji Shunda Steel Structure Engineering Co., Ltd. (河北宏基舜达钢结构工程股份有限公司) is a leading manufacturer and supplier of steel structure hangars and prefabricated buildings. With years of experience in the industry, the company has established itself as a trusted name in providing high-quality, cost-effective solutions for aviation and industrial infrastructure.

Hebei Hongji Shunda specializes in custom-designed steel buildings, including airplane hangars, industrial warehouses, and agricultural facilities. Their commitment to innovation, quality, and customer satisfaction has earned them a strong reputation in both domestic and international markets. The company adheres to strict quality control standards and utilizes state-of-the-art manufacturing technologies to ensure that every product meets the highest industry benchmarks.

For more information about Hebei Hongji Shunda Steel Structure Engineering Co., Ltd., visit their official website: Hebei Hongji Shunda.

Product Page: Airplane Hangar Metal Buildings

To explore the full range of airplane hangar metal buildings offered by Hebei Hongji Shunda, visit their product page: Airplane Hangar Metal Buildings.

Product Images

Below are the product images of airplane hangar metal buildings to provide a visual representation of the structures:

Why Choose Hebei Hongji Shunda?

Hebei Hongji Shunda Steel Structure Engineering Co., Ltd. stands out in the industry due to its comprehensive solutions, competitive pricing, and excellent customer service. The company’s dedication to innovation ensures that their steel hangar buildings are equipped with the latest technological advancements. Additionally, their global distribution network allows for efficient delivery to clients worldwide.

For aviation facilities and industrial clients seeking reliable, durable, and cost-effective solutions, Hebei Hongji Shunda is the ideal partner. Their customizable designs and high-quality materials ensure that every steel hangar building meets the unique needs of its users.

Conclusion

Airplane hangar metal buildings represent a modern and efficient solution for aviation infrastructure. With their modular design, durable construction, and customizable configurations, these steel structure hangars are well-suited for a wide range of applications. Hebei Hongji Shunda Steel Structure Engineering Co., Ltd. continues to lead the industry by delivering high-quality, innovative, and cost-effective solutions that meet the evolving demands of the aviation and industrial sectors.

For more information, visit the company website or their product page to explore the full range of steel hangar buildings and prefabricated structures.

References

1. National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from

2. Hebei Hongji Shunda Steel Structure Engineering Co., Ltd. (n.d.). Airplane Hangar Metal Buildings. Retrieved from

-

Bolted Connections in Steel Frame Warehouse

NewsNov.17,2025

-

Hay Storage in Farm Metal Buildings

NewsNov.17,2025

-

Advantages of a Steel Portal Frame Shed

NewsNov.17,2025

-

The Erection Process of a Steel Building Hangar

NewsNov.17,2025

-

Energy Efficiency of Steel Dome Garage Kits

NewsNov.17,2025

-

Fire Resistance of Kit Metal Garages

NewsNov.17,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.