Sep . 27, 2025 23:40 Back to list

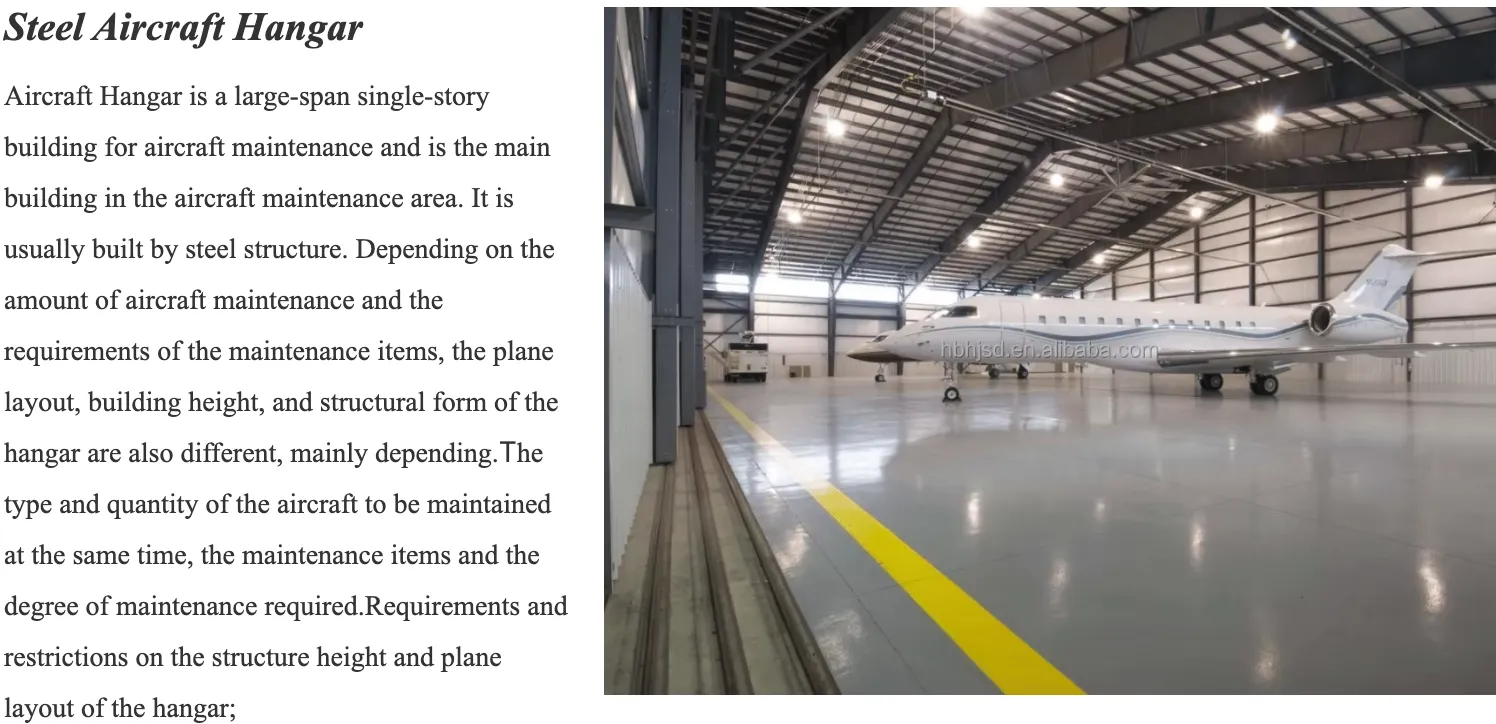

Steel hangar buildings have become a cornerstone of modern aviation infrastructure, offering a combination of durability, flexibility, and cost-effectiveness. For aviation facilities requiring robust, scalable, and quick-to-erect structures, prefabricated hangars provide an optimal solution. This article explores the technical specifications, applications, and advantages of airplane hangar metal buildings, while highlighting the expertise of Hebei Hongji Shunda Steel Structure Engineering Co., Ltd (the manufacturer behind these innovative structures).

Modern steel hangar buildings designed for aviation facilities

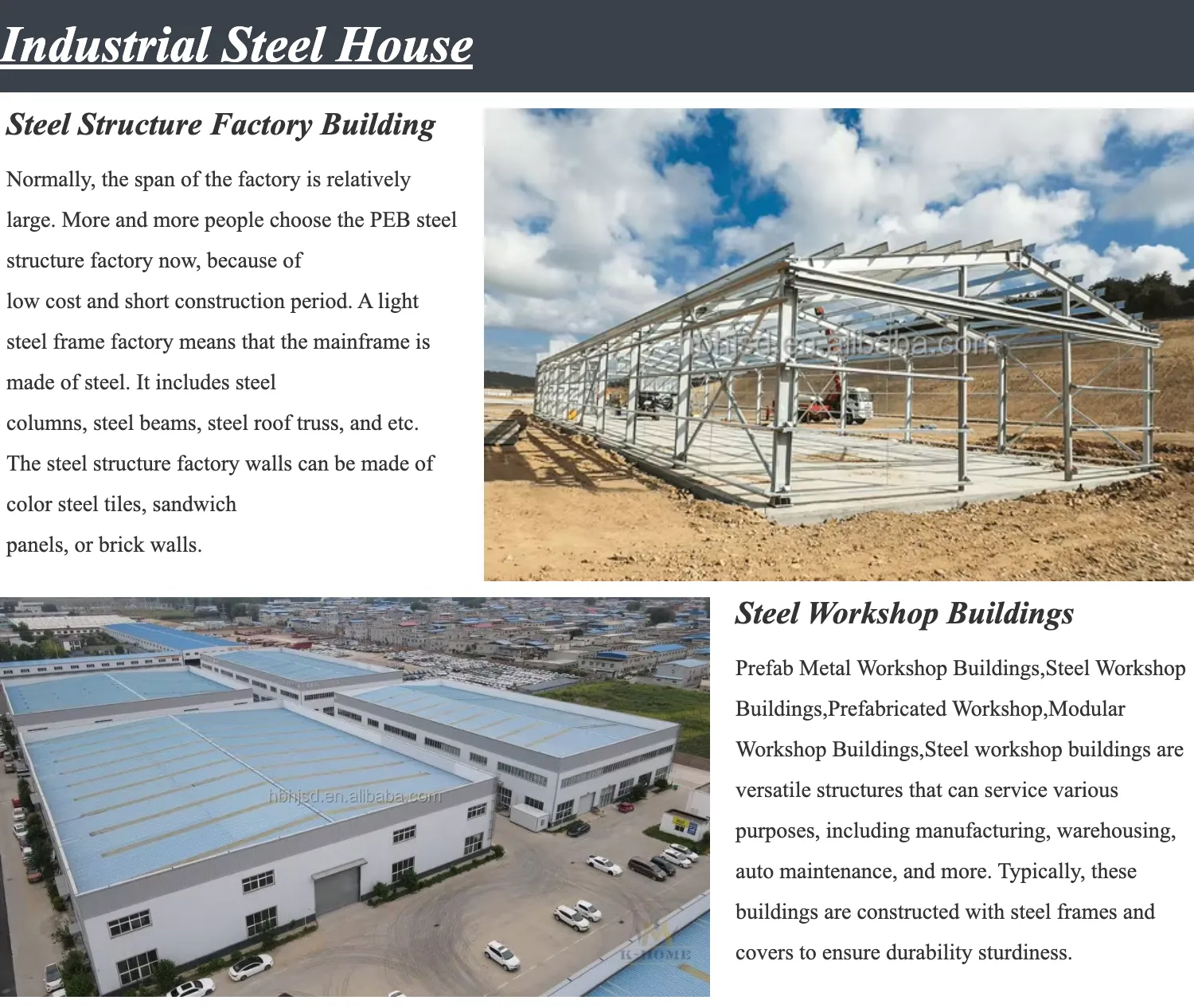

Product Overview: Steel Hangar Buildings for Aviation

Steel hangar buildings are engineered to meet the unique demands of aviation infrastructure. These structures are constructed using high-strength steel frameworks and corrugated steel panels, ensuring resilience against environmental stressors while maintaining a lightweight design. The airplane hangar metal buildings offered by Hebei Hongji Shunda are available in multiple configurations, including single-slope, double-slope, and gabled designs, tailored to accommodate various aircraft sizes and operational requirements.

The popular sizes of these hangars include 20x30m, 20x50m, and 16x36m, with heights ranging from 4m to 6m. This versatility allows for customization to suit specific needs, whether for small private aircraft or large commercial aircraft. The coverage options include single corrugated steel sheet, insulation roof with single steel sheet wall, and single steel sheet or only roof, providing flexibility in insulation and thermal management.

Gate sizes are also customizable, with standard options including 18x4.5m, 18x5m, and 14x3.5m. These dimensions ensure smooth access for aircraft and equipment, while the prefabricated design minimizes on-site construction time and labor costs. For more details, visit the product page.

Steel structure hangar with customizable dimensions

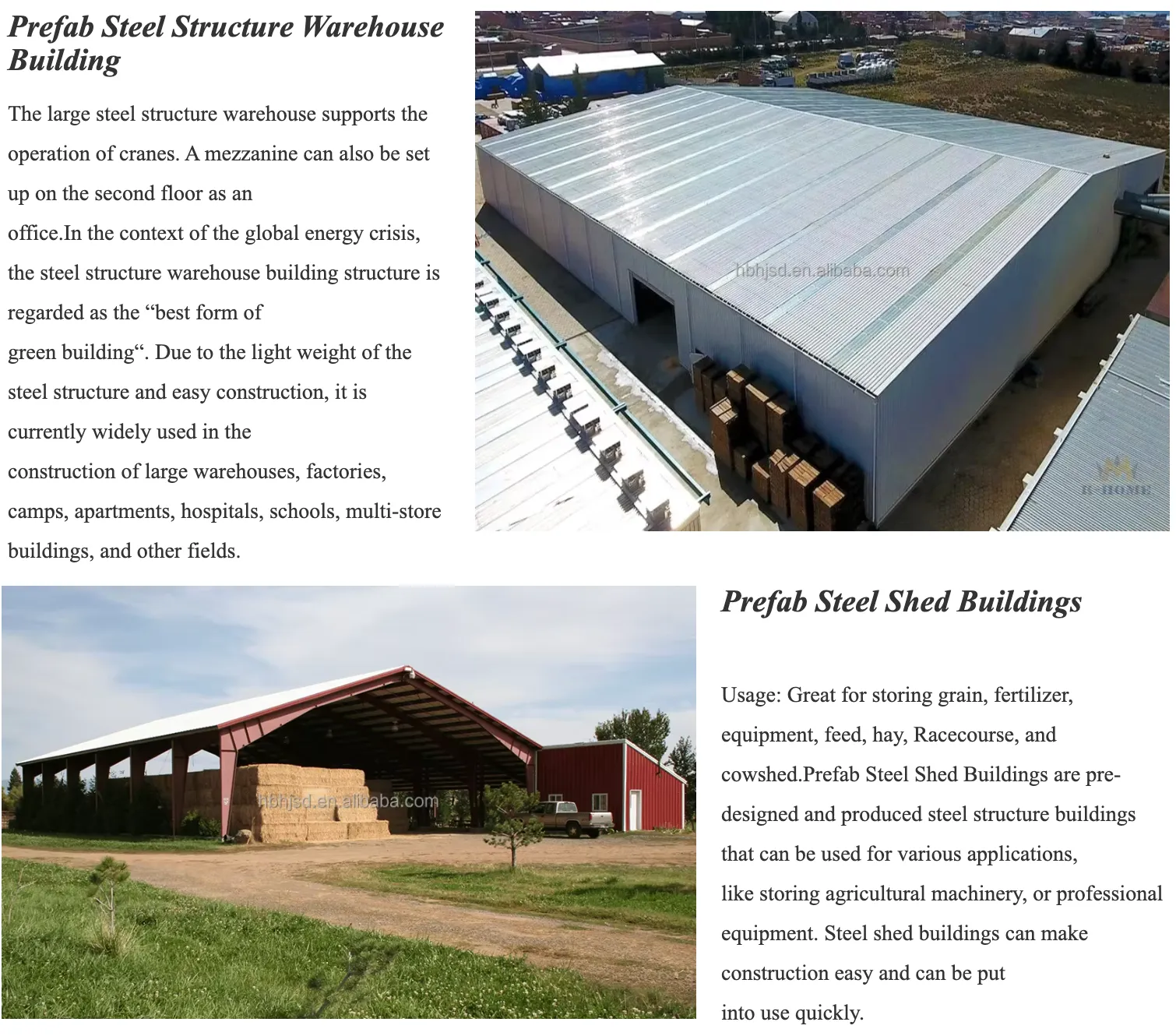

Technical Specifications: Precision Engineering for Aviation

The technical specifications of airplane hangar metal buildings reflect the manufacturer's commitment to quality and innovation. Below is a detailed table summarizing the key parameters:

| Parameter | Details |

|---|---|

| Material | High-strength steel framework, corrugated steel panels |

| Dimensions | Customizable (e.g., 20x30m, 20x50m, 16x36m) |

| Height | 4m, 5m, 6m (adjustable) |

| Coverage Options | Single corrugated steel sheet, insulated roof with single steel sheet wall, or single steel sheet only |

| Gate Sizes | 18x4.5m, 18x5m, 14x3.5m (customizable) |

| Wind Load Capacity | Up to 1.5 kN/m² (per ASTM standards) |

| Seismic Resistance | Designed for seismic zones up to 8 on the Richter scale |

| Fire Resistance | Class A fire rating (per UL 790 standards) |

These specifications ensure that the hangars meet rigorous safety and performance standards, as outlined by the National Institute of Standards and Technology (NIST). NIST's research on structural integrity and material performance provides a framework for evaluating the durability of such buildings, reinforcing their reliability for aviation applications.

Modular construction of prefabricated hangars

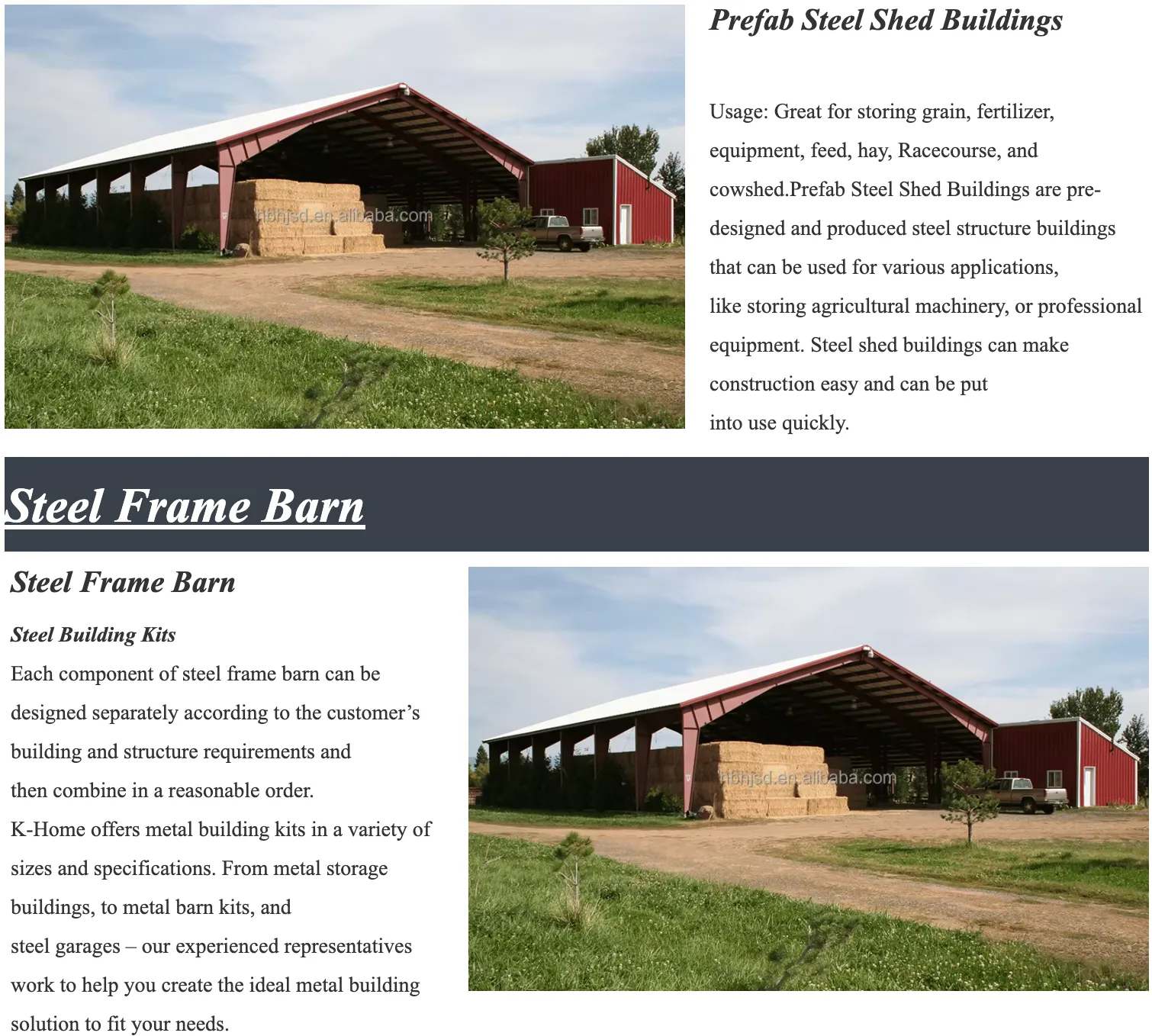

Key Advantages: Why Choose Steel Hangar Buildings?

Steel hangar buildings offer several distinct advantages over traditional construction methods. These benefits include:

- Quick Installation: The prefabricated design allows for rapid assembly, reducing construction time by up to 50% compared to conventional methods.

- Cost-Effectiveness: Lower material and labor costs, combined with long-term maintenance savings, make steel hangars a financially viable option.

- Customizability: The ability to tailor dimensions, configurations, and coverage options ensures the structure meets specific operational needs.

- Environmental Sustainability: Steel is a recyclable material, and the energy-efficient design reduces the carbon footprint of the facility.

- Longevity: With proper maintenance, steel hangars can last over 30 years, providing a durable solution for aviation infrastructure.

These advantages align with NIST's emphasis on sustainable and resilient infrastructure. According to NIST, "The integration of high-performance materials and modular construction techniques is critical for modernizing industrial facilities" (NIST Research).

Interior layout of a steel hangar for aircraft storage

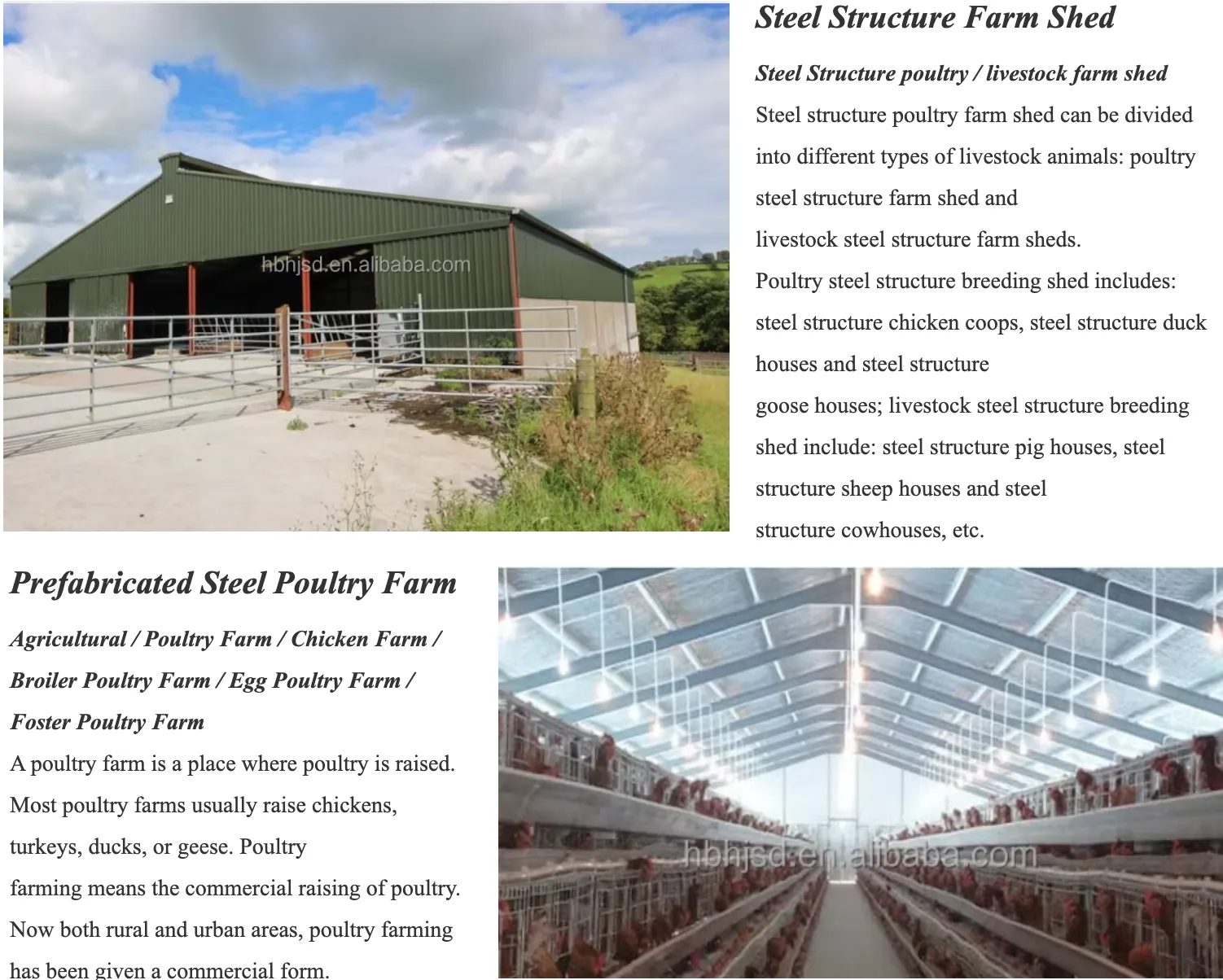

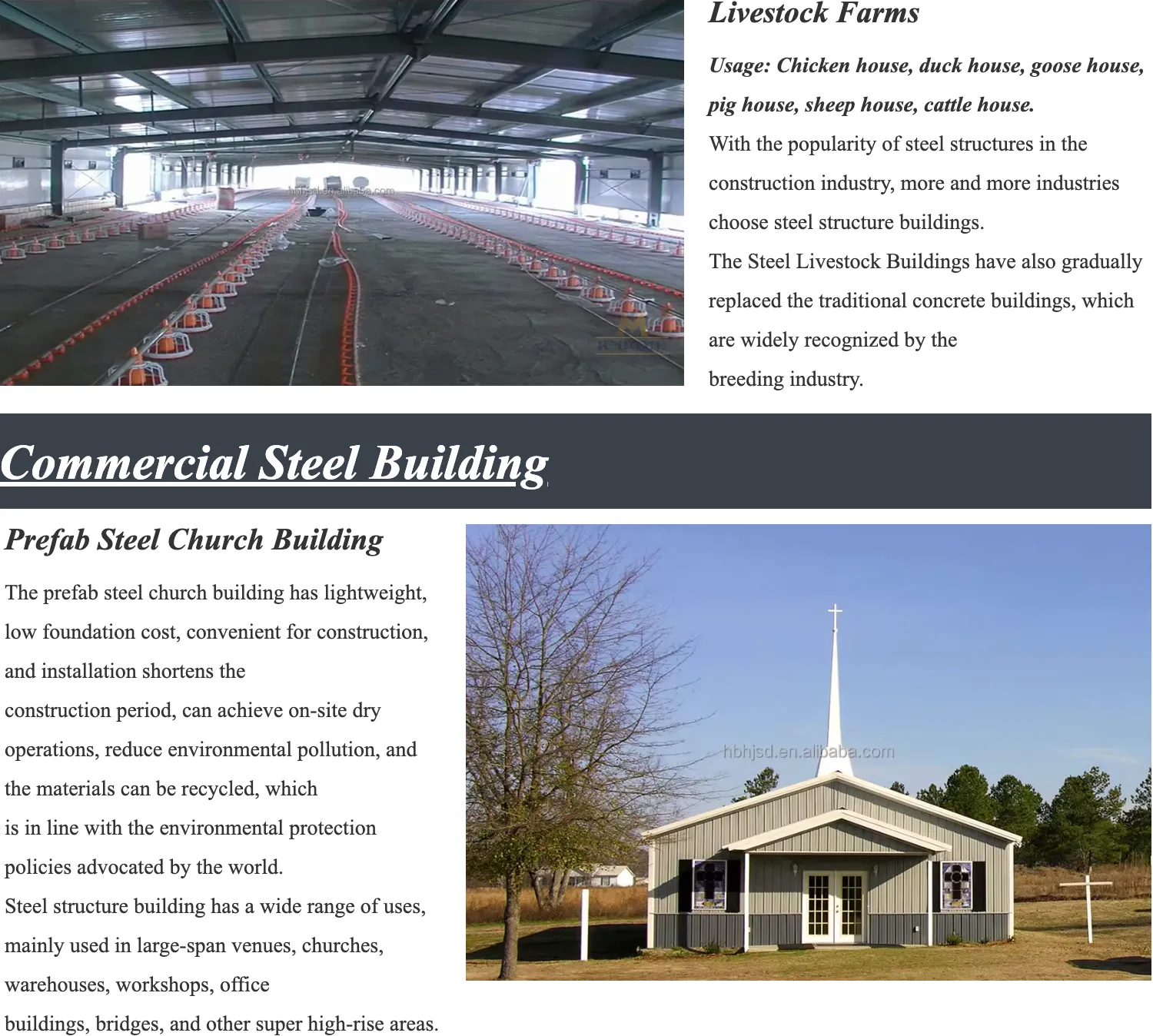

Applications: Versatile Use Cases for Airplane Hangars

Airplane hangar metal buildings are suitable for a wide range of applications, including:

- Aircraft Storage: Providing secure, weather-protected spaces for private and commercial aircraft.

- Aviation Maintenance: Equipped with overhead cranes and tool storage, these hangars support routine maintenance and repairs.

- Flight Training Facilities: Ideal for flight schools requiring spacious, durable structures for training aircraft.

- Emergency Response Units: Rapid deployment of hangars for temporary storage or maintenance during disasters or military operations.

- Commercial Aviation Hubs: Scalable solutions for airports needing additional hangar space for expanding fleets.

The flexibility of steel hangar buildings makes them a preferred choice for aviation stakeholders seeking adaptable and future-proof infrastructure.

Exterior view of a modern steel hangar

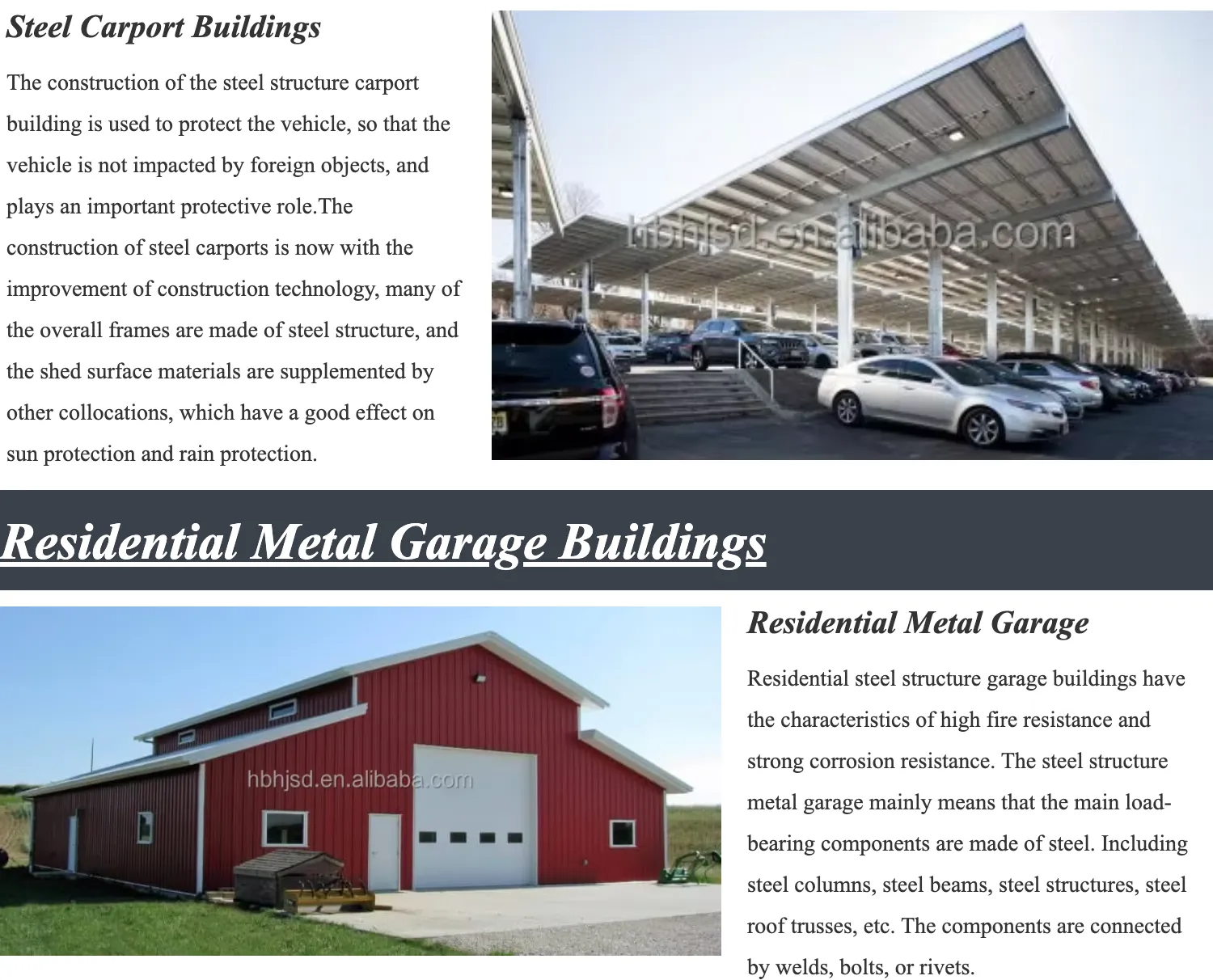

Company Background: Hebei Hongji Shunda Steel Structure Engineering Co., Ltd

Hebei Hongji Shunda Steel Structure Engineering Co., Ltd is a leading manufacturer of steel structure buildings, specializing in airplane hangars, industrial warehouses, and agricultural facilities. With over a decade of experience, the company has established itself as a trusted provider of prefabricated steel solutions for clients worldwide.

Founded in 2010, Hebei Hongji Shunda has consistently focused on innovation, quality, and customer satisfaction. The company's commitment to sustainable practices and technological advancement has enabled it to deliver high-performance structures that meet international standards. Their products are exported to over 50 countries, including the United States, Europe, and Asia.

For more information about the company, visit the official website.

Construction process of a steel hangar

Conclusion: The Future of Aviation Infrastructure

Airplane hangar metal buildings represent a significant advancement in aviation infrastructure, combining durability, flexibility, and cost-efficiency. With their modular design, customizable options, and compliance with rigorous safety standards, these structures are well-suited for a wide range of applications. Hebei Hongji Shunda Steel Structure Engineering Co., Ltd's expertise in prefabricated steel solutions ensures that clients receive high-quality, reliable facilities that meet modern aviation demands.

As the aviation industry continues to evolve, the need for innovative and sustainable infrastructure will only grow. Steel hangar buildings are poised to play a pivotal role in this transformation, offering a future-ready solution for aviation stakeholders worldwide.

Steel hangar accommodating a commercial aircraft

References

National Institute of Standards and Technology (NIST). "Research on Structural Integrity and Material Performance." Retrieved from https://www.nist.gov/.

Hebei Hongji Shunda Steel Structure Engineering Co., Ltd. "Product Specifications and Applications." Retrieved from https://www.hongjishunda.com.

-

Bolted Connections in Steel Frame Warehouse

NewsNov.17,2025

-

Hay Storage in Farm Metal Buildings

NewsNov.17,2025

-

Advantages of a Steel Portal Frame Shed

NewsNov.17,2025

-

The Erection Process of a Steel Building Hangar

NewsNov.17,2025

-

Energy Efficiency of Steel Dome Garage Kits

NewsNov.17,2025

-

Fire Resistance of Kit Metal Garages

NewsNov.17,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.