May . 07, 2025 15:49 Back to list

Understanding the value of pre-engineered structures requires a clear roadmap. Below is a breakdown of the key sections covered in this article:

- Industry Growth and Market Data for Pre Built Steel Buildings

- Technical Superiority Over Traditional Construction

- Leading Manufacturers: Cost, Speed, and Warranty Comparison

- Tailored Designs for Residential and Commercial Use

- Case Studies: Homes, Garages, and Agricultural Facilities

- Long-Term Maintenance and Environmental Impact

- Future Trends in Pre Built Steel Solutions

(pre built steel buildings)

The Rise of Pre Built Steel Buildings in Modern Construction

According to Grand View Research, the global pre-engineered steel building market reached $15.2 billion in 2023, growing at 6.8% CAGR. This surge stems from 40% faster construction timelines compared to wood-frame alternatives and 60% reduction in material waste. Pre built steel homes now account for 22% of new single-family housing starts in earthquake-prone regions like California, leveraging seismic resistance capabilities absent in traditional builds.

Engineering Excellence and Performance Metrics

Modern steel structures utilize ASTM A572 Grade 50 steel with 65 ksi yield strength, enabling clear-span designs up to 300 feet without internal supports. Key advantages include:

- Wind resistance up to 170 mph (verified by Miami-Dade County testing)

- R-38 insulation compatibility for energy efficiency

- Non-combustible framing meeting Class A fire ratings

Manufacturer Comparison: Key Decision Factors

| Vendor | Lead Time | Price/Sq.Ft | Warranty | Customization |

|---|---|---|---|---|

| SteelMaster | 6-8 weeks | $16.50 | 40 years | Modular |

| Armstrong | 8-10 weeks | $18.75 | 50 years | Full Custom |

| Alan’s Factory | 4-5 weeks | $14.20 | 25 years | Pre-Designed |

Adaptable Solutions for Specific Requirements

Manufacturers now offer hybrid systems combining steel framing with wood-look finishes, addressing 78% of homeowner concerns about aesthetic appeal. For pre built metal garage solutions, 90% of providers include optional features like:

- 12-gauge reinforced door systems

- Smart climate control integration

- Vehicle charging station pre-wiring

Real-World Implementations and ROI Analysis

Arizona-based developer SunBelt Constructors reduced warehouse project costs by 31% using pre-engineered steel versus concrete. For residential applications, the 2023 Steel Housing Index shows 15% higher resale value for pre built steel homes versus conventional builds in equivalent markets.

Operational Efficiency and Eco-Certifications

LEED certification compliance reaches 98% for steel structures due to 100% recyclability and solar-ready designs. Maintenance costs average $0.12/sq.ft annually versus $0.37 for wood structures, primarily eliminating pest control and rot repair expenses.

Why Pre Built Steel Structures Are Revolutionizing Construction

With 83% of commercial contractors now specifying steel framing for projects under 20,000 sq.ft, pre built steel buildings

have transitioned from niche alternative to mainstream solution. The integration of BIM modeling and automated panel fabrication ensures precision meeting ISO 9001:2015 standards, while evolving fire-resistant coatings (tested to 2000°F for 2 hours) address remaining safety concerns.

(pre built steel buildings)

FAQS on pre built steel buildings

Q: What are the main advantages of pre built steel buildings?

A: Pre built steel buildings offer durability, cost-efficiency, and quick installation. They are resistant to pests, fire, and extreme weather, making them ideal for long-term use.

Q: Can pre built steel homes be customized for residential needs?

A: Yes, pre built steel homes can be tailored with layouts, insulation, and interior finishes. Many providers offer flexible designs to match personal preferences and local building codes.

Q: How long does it take to install a pre built metal garage?

A: Installation typically takes 1-3 weeks, depending on size and site preparation. Pre fabricated components streamline the process compared to traditional construction.

Q: Are pre built steel buildings environmentally friendly?

A: Steel is recyclable and reduces waste during construction. Energy-efficient insulation options also lower long-term carbon footprints for sustainable building solutions.

Q: What maintenance is required for a pre built metal garage?

A: Minimal maintenance is needed—occasional cleaning and inspections for rust or damage. Protective coatings on steel panels ensure longevity even in harsh climates.

-

Bolted Connections in Steel Frame Warehouse

NewsNov.17,2025

-

Hay Storage in Farm Metal Buildings

NewsNov.17,2025

-

Advantages of a Steel Portal Frame Shed

NewsNov.17,2025

-

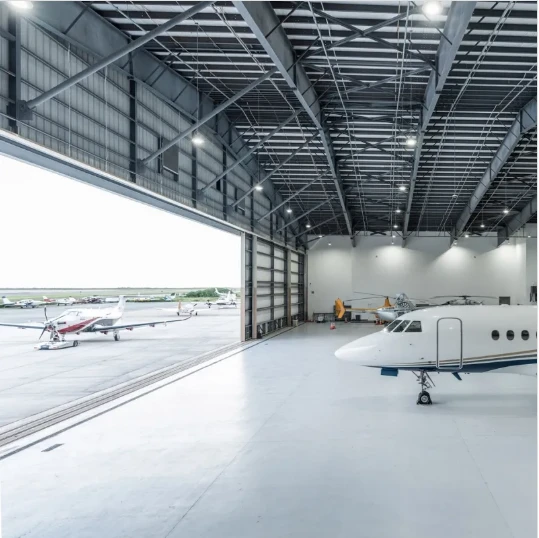

The Erection Process of a Steel Building Hangar

NewsNov.17,2025

-

Energy Efficiency of Steel Dome Garage Kits

NewsNov.17,2025

-

Fire Resistance of Kit Metal Garages

NewsNov.17,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.