Oct . 17, 2025 11:10 Back to list

A Practical Insider’s Guide to Residential Steel Garage Buildings

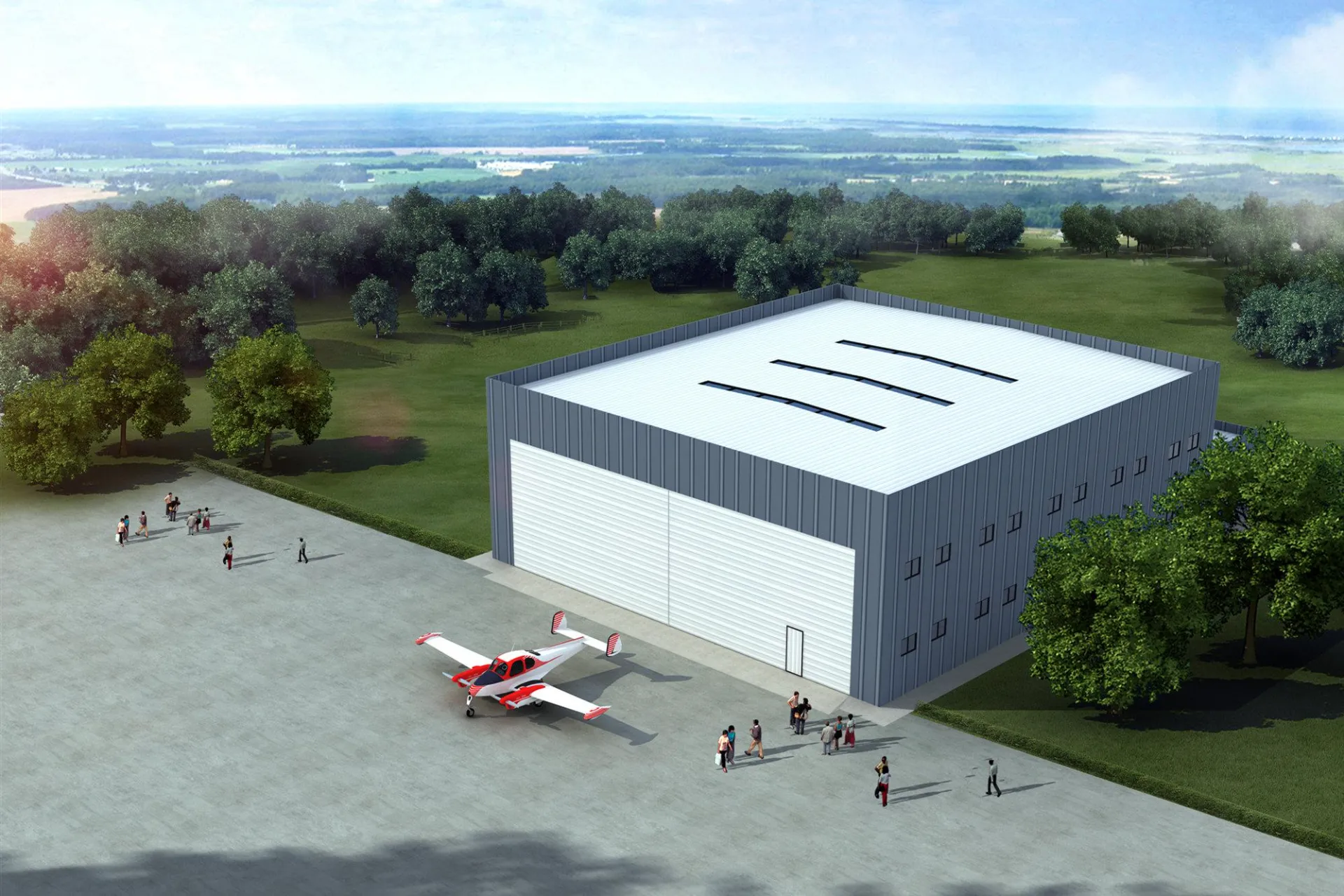

If you’ve been shopping around for garages, you’ve likely noticed how fast the market is pivoting to steel. Here’s the short story: residential steel garage buildings borrow engineering DNA from aircraft hangars—overbuilt (in a good way), precise, and efficient. In fact, I recently toured HongJi ShunDa’s facility in Hebei, and the hangar-grade detailing trickles straight into their residential kits. It shows.

Industry trends (what buyers actually ask for)

Three big shifts: faster installs, higher wind/snow ratings, and real sustainability. Many customers say they want “no-drama ownership,” which usually means galvanized frames, factory-drilled members, and clear documentation. Also, rising lumber volatility nudges folks to steel—predictable pricing is surprisingly comforting.

Technical backbone and real-world specs

HongJi ShunDa’s hangar tech (portal frames, Z/C purlins, high-strength fasteners) adapts nicely to residential steel garage buildings. Below is a typical two–three car configuration—adjustable, of course.

| Parameter | Spec (≈/range; real-world use may vary) |

|---|---|

| Footprint | ≈ 24–36 ft wide x 24–30 ft deep; eave height 10–14 ft |

| Primary frame | Welded H-beams, Q355/Q235 or ASTM A36/A992; shop-primed or HDG (ASTM A123) |

| Secondary members | Z/C purlins, cold-formed galvanized (ASTM A653 G90+) |

| Panels | 26–24 ga pre-painted steel, R-panel or standing seam roof |

| Design loads | Wind up to 140–170 mph (ASCE 7), ground snow 30–70 psf (site-specific) |

| Service life | 30–50+ years with proper coatings and maintenance (ISO 12944) |

Process, testing, and compliance (the unglamorous but vital bits)

- Materials: commercial-grade steel coils; shot-blast, precision cut; submerged-arc welding on frames.

- Coatings: hot-dip galvanizing (ASTM A123) or pre-galv (ASTM A653) + paint; coastal options per ISO 12944 C4/C5.

- Methods: portal-frame engineering, bolted connections, factory punching for fast alignment.

- Testing: tensile/impact (AISC/AISI); salt-spray (ASTM B117); bolt proof loads; fit-up trials.

- Standards: IBC/IRC local adoption, ASCE 7 wind/snow, AISC 360, AISI S100; CE EN 1090 (when exported to EU).

Applications and advantages

Daily-driver parking, workshop bays, EV charging, hobby studios, or a tall-bay for an RV or boat. The big wins with residential steel garage buildings are speed (panelized kits), predictable cost, and low maintenance. Anti-corrosion detailing plus fewer pest issues—termite drama goes to zero.

Vendor snapshot (who does what well?)

| Vendor | Steel/Certs | Lead Time | Price ≈ | Notes |

|---|---|---|---|---|

| HongJi ShunDa (No. 1 YuLong Road, JinZhou, Shijiazhuang, Hebei) | Q355/A36; ISO 9001; EN 1090 option | 3–8 weeks | $18–$35/sq ft | Hangar-grade frames; strong docs; export savvy |

| Local Pole-Barn Builder | Mixed; fewer factory certs | 2–6 weeks | $20–$40/sq ft | Fast permits; wood posts may need more upkeep |

| Generic Kit Seller | Varies; check mill certs | 4–10 weeks | $15–$28/sq ft | Low price; confirm engineering stamps |

Customization and delivery flow

Sketch your footprint, door types (roll-up, sectional, full-glass), insulation (R-13 to R-30+), and finishes. Submittals include anchor-bolt plans and stamped calcs (where required). Fabrication, QC, then flat-pack shipping. On-site, a small crew and a scissor lift usually do it. To be honest, site prep and slab timing cause more delays than the steel.

Mini case studies

Mountain town, 36x28: upgraded snow load 60 psf, standing seam roof, R-19 walls. “Winter was a non-event,” the owner told me—no ice-dam headaches.

Coastal lot, 30x26: HDG frames + ISO 12944 C4 paint, stainless fasteners. After 18 months, corrosion readings stayed near baseline—impressive for salt air.

Closing thought

If you want a set-it-and-forget-it building, residential steel garage buildings—especially those borrowing hangar engineering—are tough to beat. Not flashy, just solid, which is kind of the point.

Authoritative citations

- AISC 360-22: Specification for Structural Steel Buildings

- ASCE/SEI 7-22: Minimum Design Loads and Associated Criteria for Buildings

- IBC 2021: International Building Code

- ASTM A123/A123M & ASTM A653/A653M: Zinc Coatings and Sheet Steel

- ISO 12944: Corrosion Protection of Steel Structures by Protective Paint Systems

-

Bolted Connections in Steel Frame Warehouse

NewsNov.17,2025

-

Hay Storage in Farm Metal Buildings

NewsNov.17,2025

-

Advantages of a Steel Portal Frame Shed

NewsNov.17,2025

-

The Erection Process of a Steel Building Hangar

NewsNov.17,2025

-

Energy Efficiency of Steel Dome Garage Kits

NewsNov.17,2025

-

Fire Resistance of Kit Metal Garages

NewsNov.17,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.