Sep . 12, 2025 05:40 Back to list

When it comes to constructing durable and efficient aviation infrastructure, Airplane Hangar Metal Buildings have emerged as a transformative solution in the steel structure engineering industry. These prefabricated hangars, developed by Hebei Hongji Shunda Steel Structure Engineering Co., Ltd, combine cutting-edge technology with cost-effective design to meet the evolving needs of modern aviation and logistics sectors. This article delves into the features, advantages, technical specifications, and applications of these innovative structures, while also highlighting the company's commitment to quality and innovation.

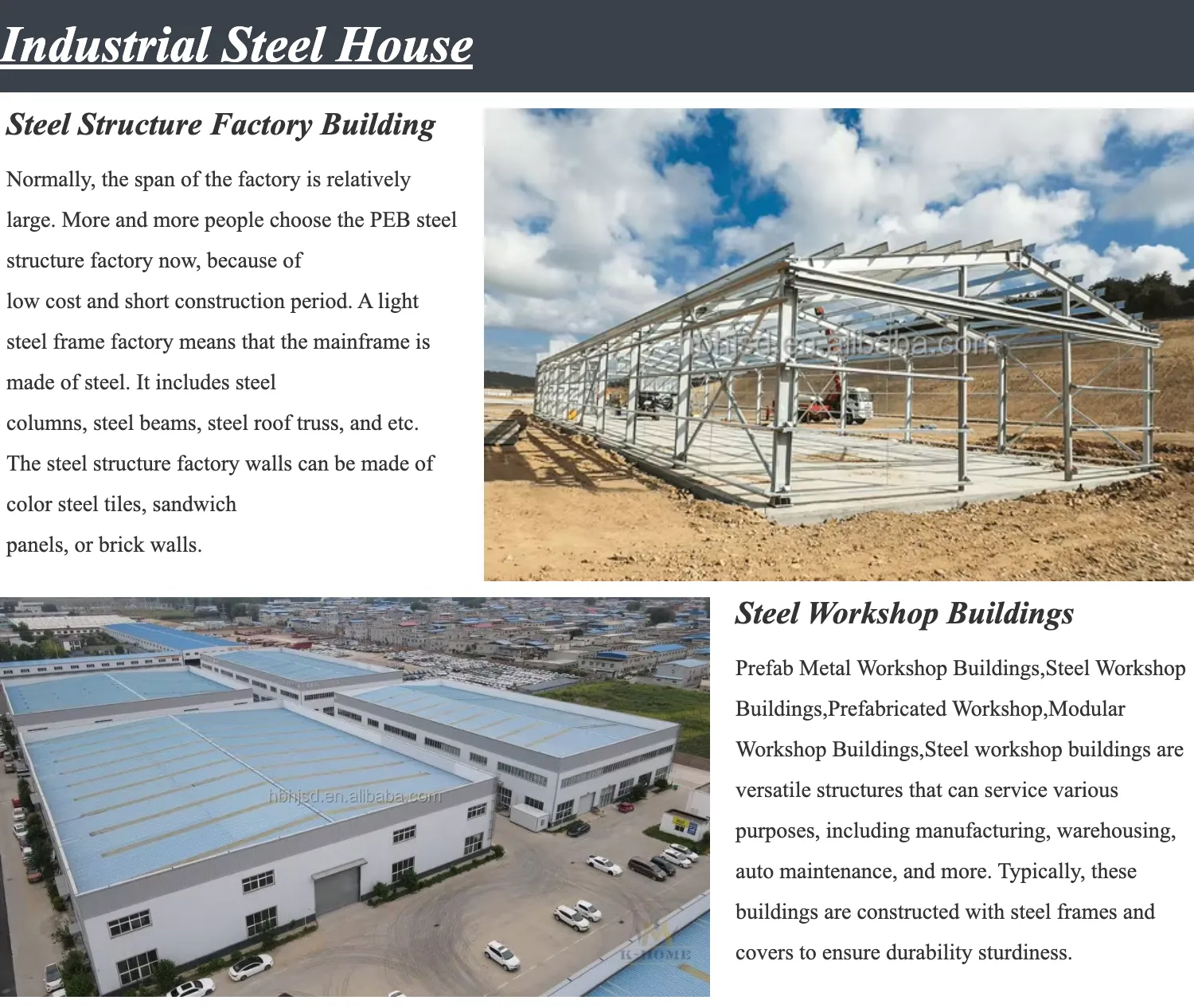

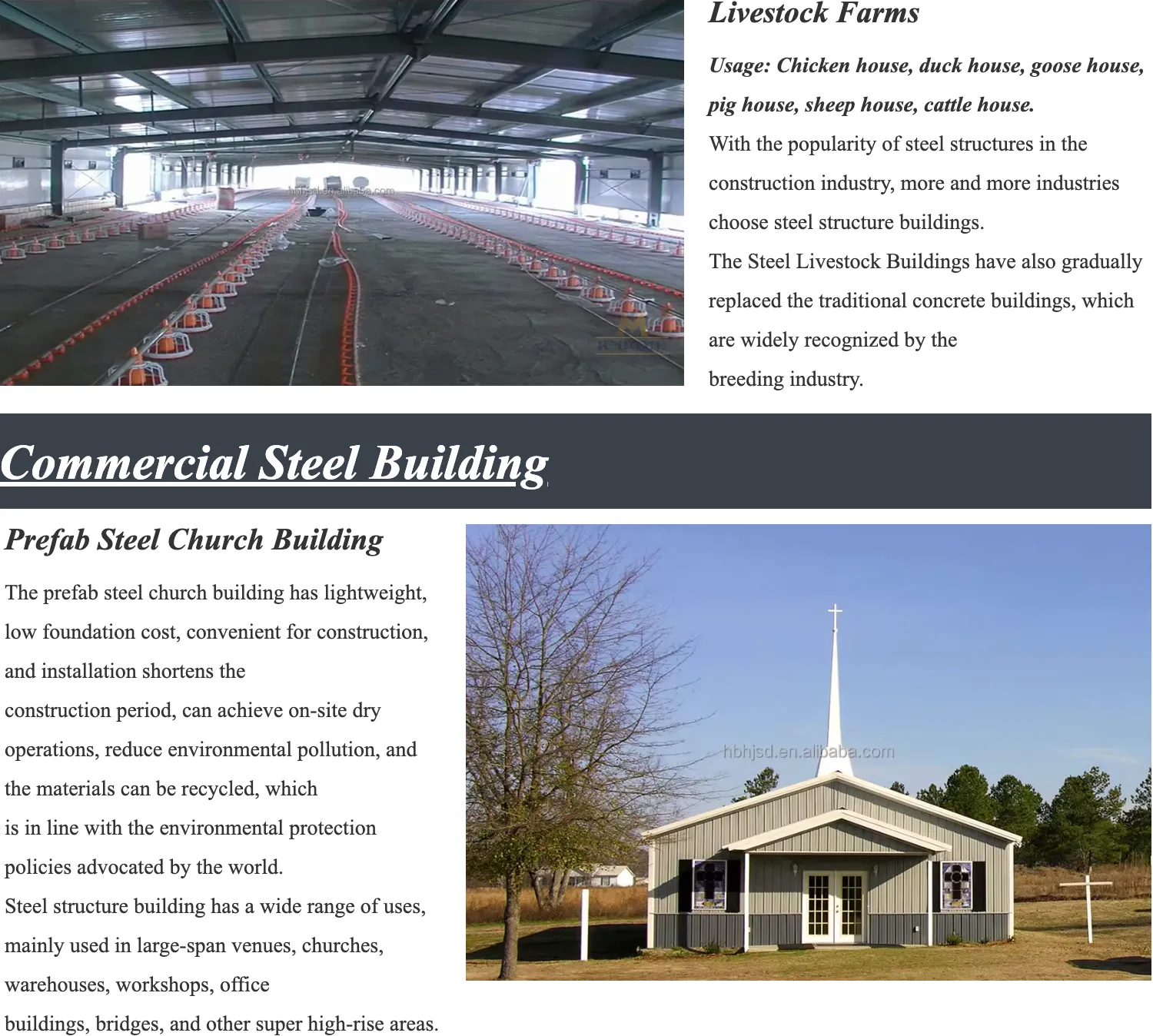

Product Overview: Steel Structure Hangars for Modern Aviation

The Airplane Hangar Metal Buildings are engineered to provide robust, customizable, and long-lasting solutions for aircraft storage, maintenance, and operational facilities. These structures are designed using high-quality steel materials, ensuring structural integrity while maintaining flexibility in design. The product line includes steel hangar buildings, prefabricated hangars, and steel structure hangars, catering to a wide range of applications from small-scale aviation operations to large commercial airports.

Figure 1: A modern steel structure hangar showcasing its durable and aerodynamic design.

Key Features and Advantages of Airplane Hangar Metal Buildings

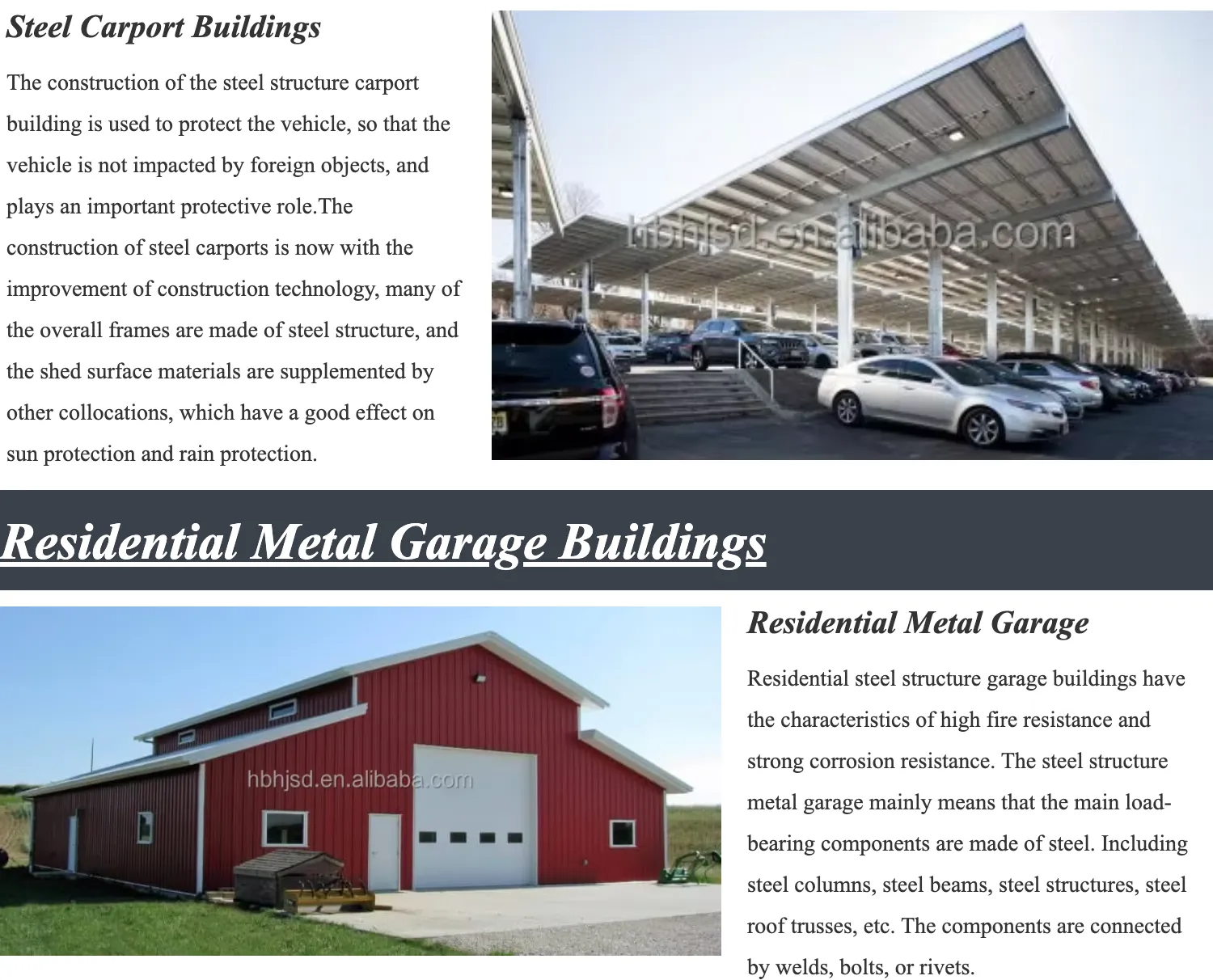

One of the standout features of these hangars is their modular design, which allows for rapid assembly and disassembly. This adaptability makes them ideal for temporary or expanding facilities. Additionally, the use of single corrugated steel sheets and insulated roofs ensures energy efficiency and weather resistance, making these structures suitable for diverse climates.

Figure 2: The interior layout of a steel hangar, highlighting its spacious and functional design.

1. Durability and Strength

Constructed with high-grade steel, these hangars are engineered to withstand extreme weather conditions, including strong winds, heavy snowfall, and seismic activity. The structural framework is designed to meet international safety standards, ensuring long-term reliability.

2. Cost-Effectiveness

The prefabricated nature of these buildings reduces construction time and labor costs. Compared to traditional concrete or masonry structures, steel hangar buildings offer a more economical solution without compromising on quality.

3. Customization Options

Hebei Hongji Shunda provides a range of customization options, including various popular sizes (e.g., 20x30m, 20x50m, 16x36m) and heights (5m, 6m, 4m). This flexibility allows clients to tailor the structure to their specific operational needs.

Technical Specifications: Precision in Every Detail

The technical specifications of Airplane Hangar Metal Buildings are meticulously designed to ensure optimal performance. Below is a comprehensive overview of the product's key parameters:

| Item | Description | Details |

|---|---|---|

| Structure Type | Steel Frame | High-strength steel with corrosion-resistant coating |

| Roofing Material | Single Corrugated Steel Sheet / Insulated Roof | Options for thermal and acoustic insulation |

| Wall Material | Single Steel Sheet or Insulated Panels | Customizable for aesthetic and functional requirements |

| Gate Dimensions | Customizable | Standard sizes: 18x4.5m, 18x5m, 14x3.5m |

| Span Options | Modular Design | Available in 20x30m, 20x50m, 16x36m, and other custom sizes |

| Height | Adjustable | Standard heights: 5m, 6m, 4m |

Figure 3: The construction process of a steel hangar, emphasizing precision and efficiency.

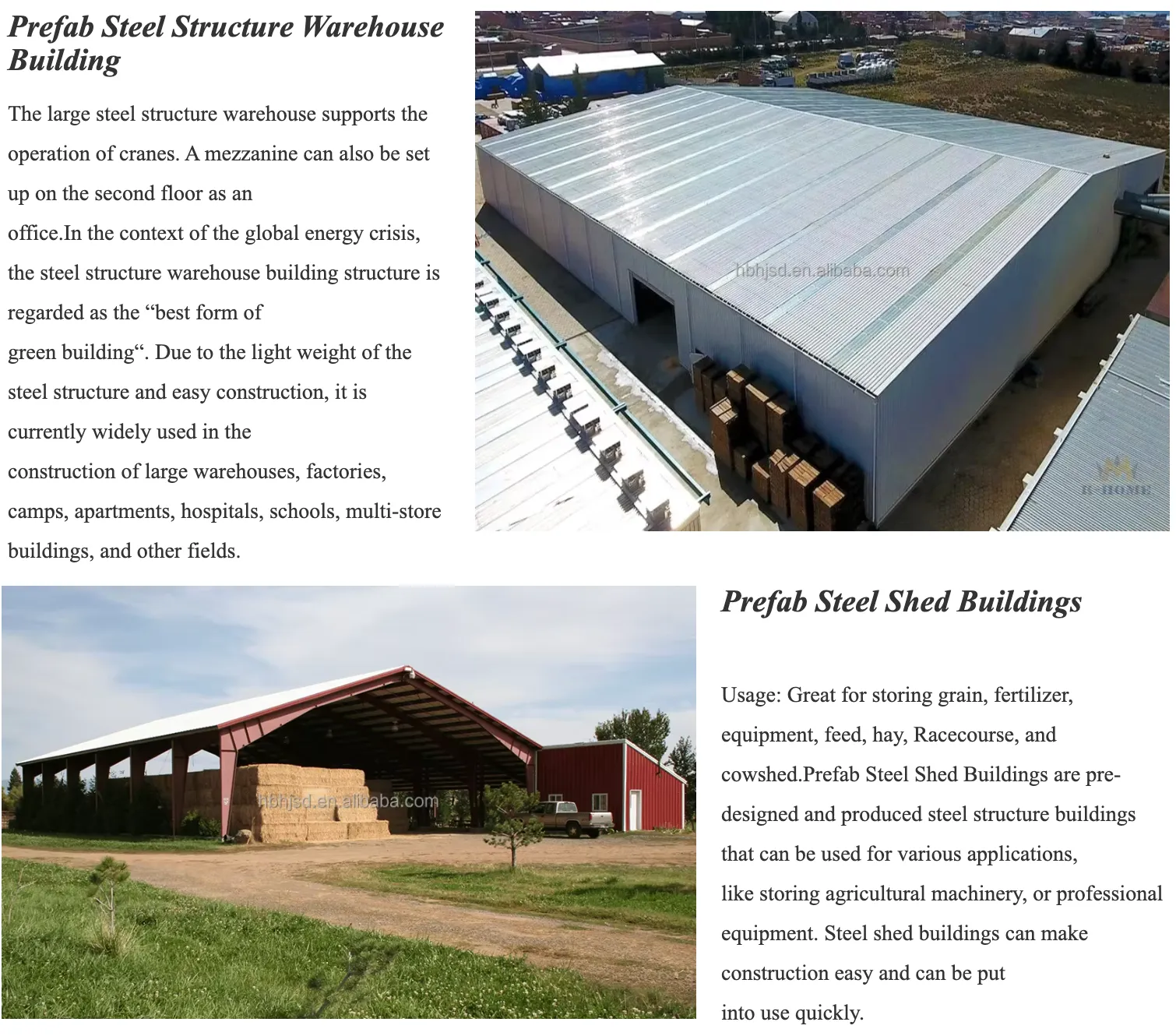

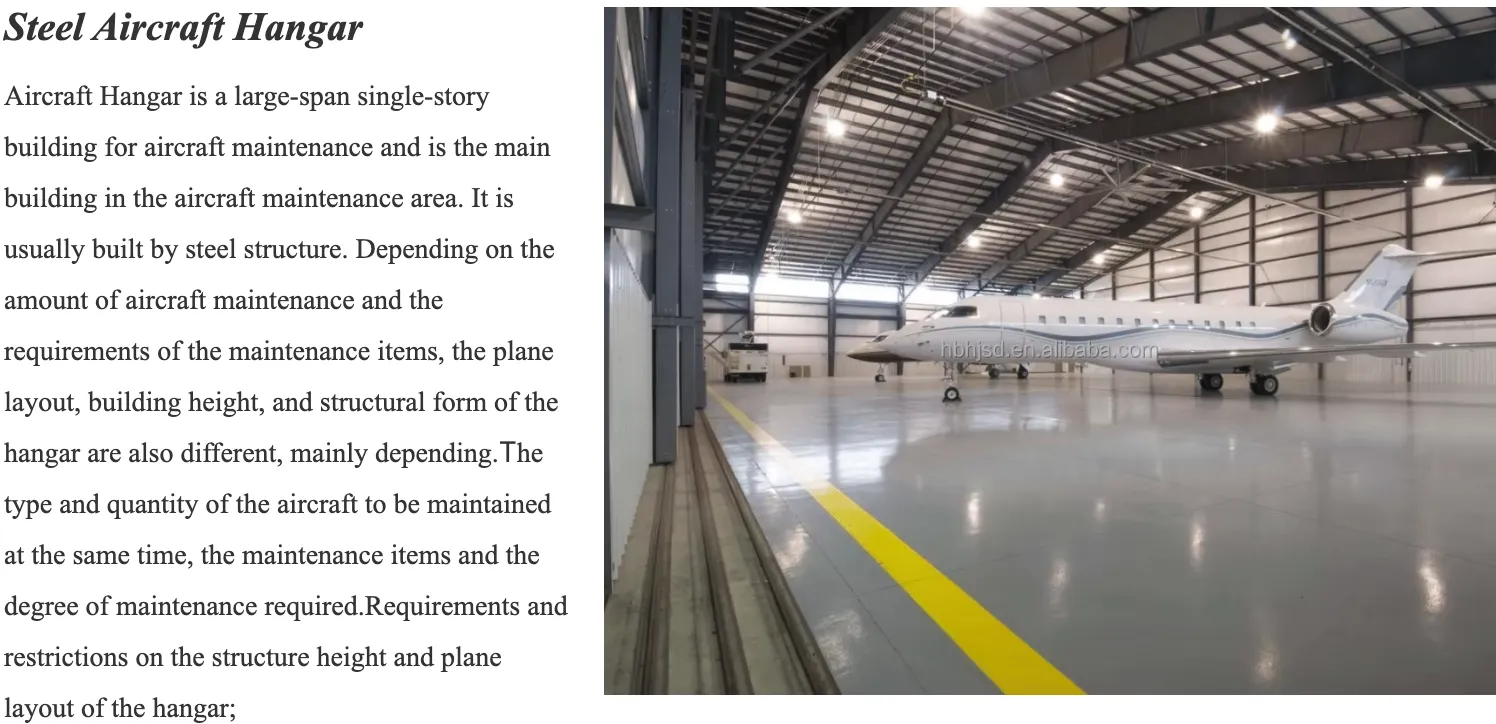

Applications in Aviation and Beyond

The versatility of Airplane Hangar Metal Buildings makes them suitable for a wide range of applications. Key use cases include:

- Aircraft Storage: Secure and protected spaces for storing commercial and private aircraft.

- Maintenance Facilities: Spacious areas equipped for regular servicing and repairs.

- Logistics and Warehousing: Efficient storage solutions for aviation-related equipment and supplies.

- Military and Defense: Durable structures for aircraft maintenance and operations in strategic locations.

Figure 4: A steel hangar integrated into a logistics facility, demonstrating its adaptability.

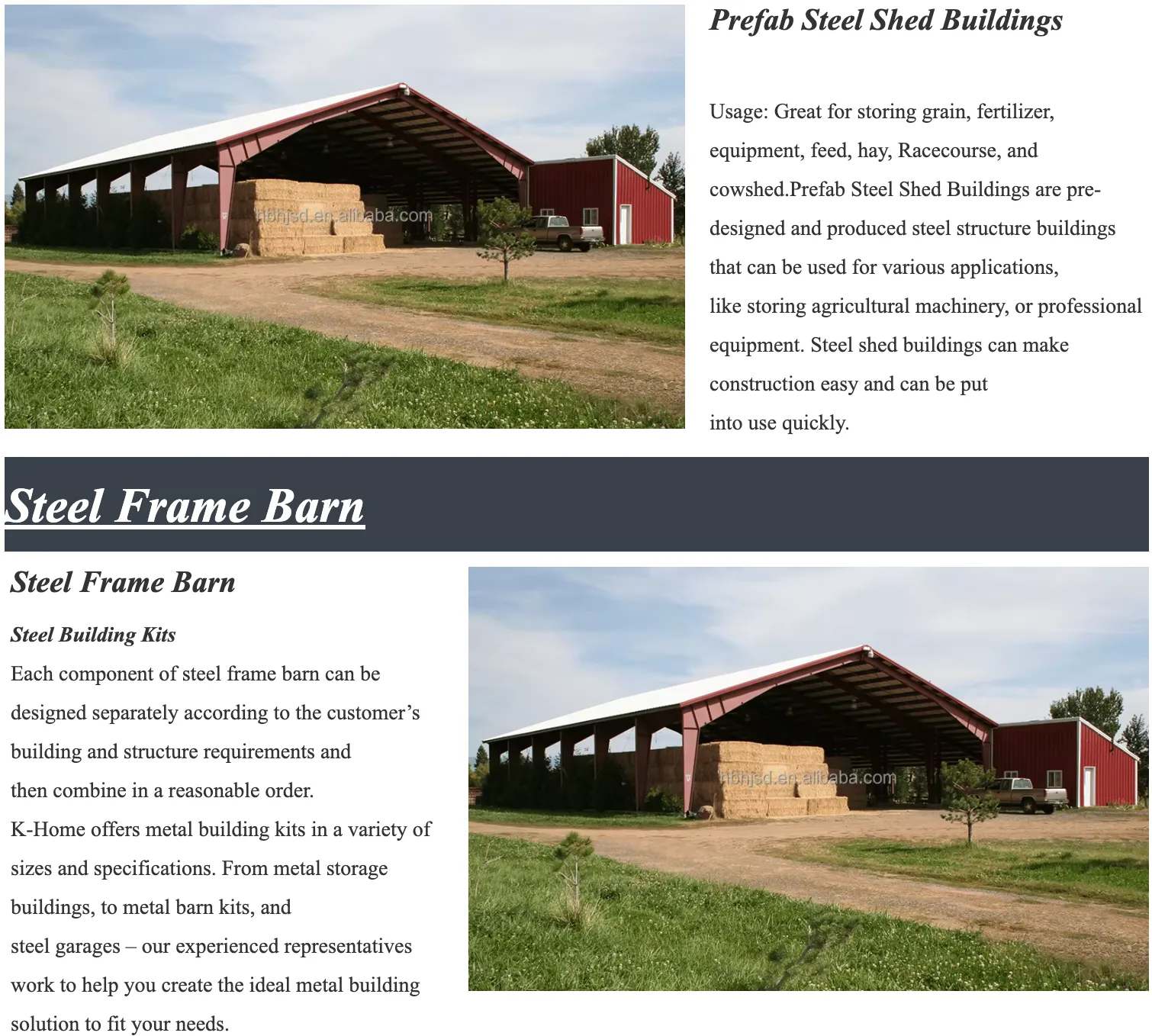

Company Background: Hebei Hongji Shunda Steel Structure Engineering Co., Ltd

Founded with a vision to revolutionize the steel structure industry, Hebei Hongji Shunda Steel Structure Engineering Co., Ltd has established itself as a leader in the design, manufacturing, and installation of prefabricated metal buildings. With over a decade of experience, the company has successfully delivered projects across multiple sectors, including aviation, agriculture, and industrial facilities.

The company's commitment to innovation is evident in its state-of-the-art manufacturing processes and adherence to international quality standards. Hebei Hongji Shunda's team of engineers and technicians ensures that every project meets the highest levels of precision and durability. Their focus on sustainability is also reflected in the use of eco-friendly materials and energy-efficient designs.

Figure 5: A glimpse into Hebei Hongji Shunda's state-of-the-art manufacturing facility.

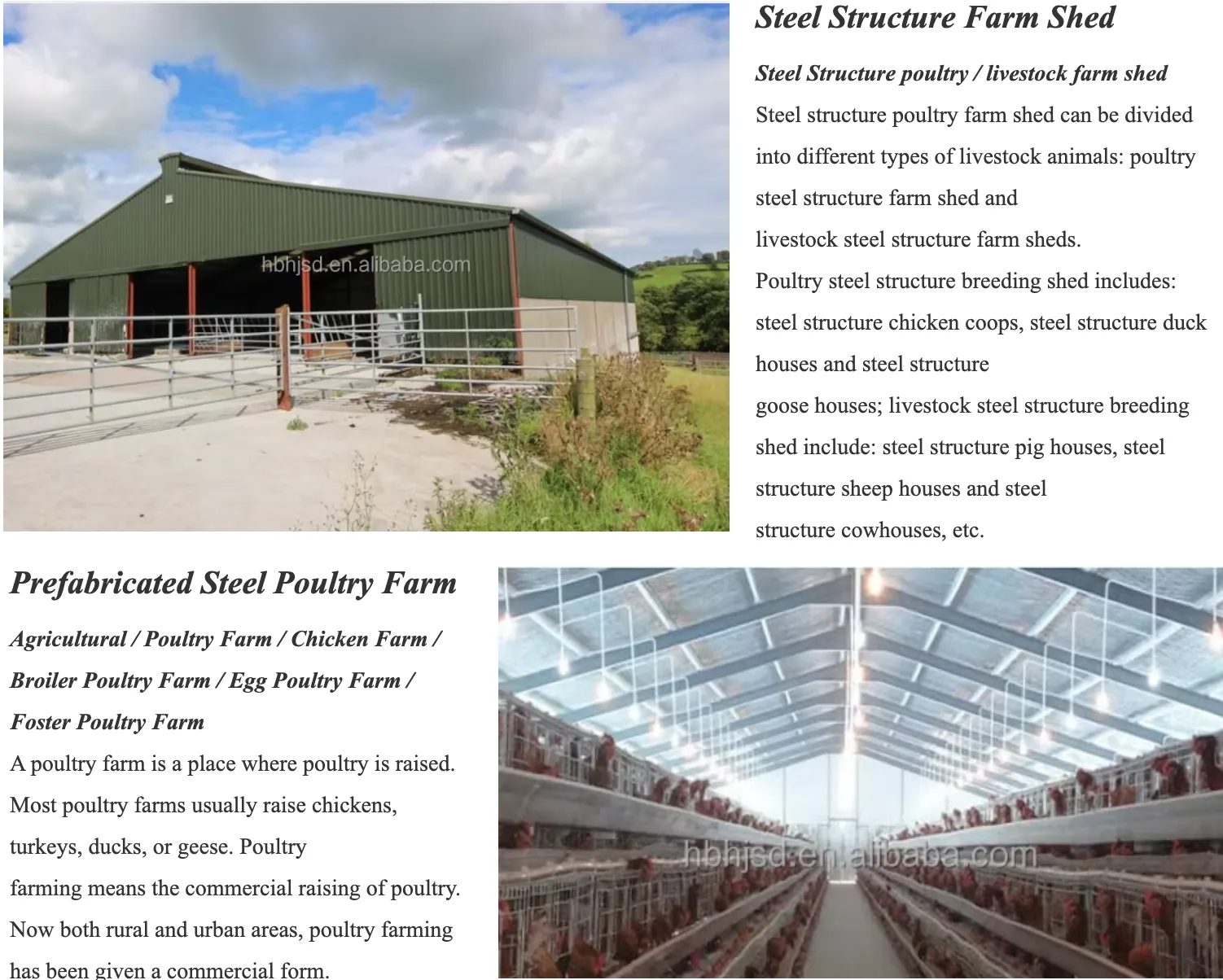

Ensuring Safety and Compliance: NIST Standards and Beyond

The structural integrity and safety of Airplane Hangar Metal Buildings are aligned with the guidelines set forth by the National Institute of Standards and Technology (NIST). While the specific page referenced in the context could not be accessed, NIST's general standards for structural engineering and materials testing provide a benchmark for the industry. These standards emphasize the importance of rigorous testing, material durability, and compliance with safety protocols, all of which are critical for aviation infrastructure.

As noted by NIST in its official publications, "Structural systems must be designed to withstand both static and dynamic loads, ensuring long-term safety and functionality." Hebei Hongji Shunda's products are engineered to meet these principles, offering clients peace of mind and long-term value.

Figure 6: A steel hangar in the process of being constructed, highlighting the company's meticulous attention to detail.

Conclusion: A Future-Ready Solution for Aviation Needs

Airplane Hangar Metal Buildings represent a significant advancement in the field of steel structure engineering. With their combination of durability, customization, and cost-effectiveness, these hangars are well-suited to meet the demands of modern aviation and logistics. Hebei Hongji Shunda Steel Structure Engineering Co., Ltd continues to lead the way in innovation, ensuring that their products not only meet but exceed industry standards.

For more information about the Airplane Hangar Metal Buildings or to explore other products offered by Hebei Hongji Shunda Steel Structure Engineering Co., Ltd, visit their official website today.

References

National Institute of Standards and Technology (NIST). (n.d.). Structural Engineering Standards. Retrieved from https://www.nist.gov

Figure 7: A completed steel hangar, showcasing its sleek design and robust construction.

-

Bolted Connections in Steel Frame Warehouse

NewsNov.17,2025

-

Hay Storage in Farm Metal Buildings

NewsNov.17,2025

-

Advantages of a Steel Portal Frame Shed

NewsNov.17,2025

-

The Erection Process of a Steel Building Hangar

NewsNov.17,2025

-

Energy Efficiency of Steel Dome Garage Kits

NewsNov.17,2025

-

Fire Resistance of Kit Metal Garages

NewsNov.17,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.