- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 05, 2025 11:06 Back to list

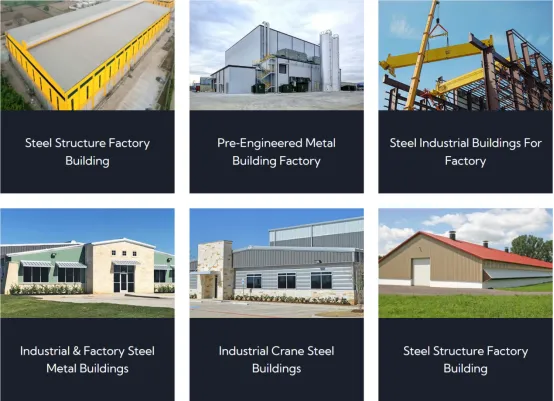

When considering industrial construction options, factory direct steel buildings offer numerous benefits that make them a preferred choice for businesses. These factory building solutions combine durability, cost-effectiveness, and flexibility to meet diverse operational needs. Unlike traditional construction methods, factory steel buildings provide faster completion times and superior structural integrity. This article explores the key advantages of choosing factory-direct steel structures for your next construction project.

Cost Savings with Factory Direct Steel Buildings

• Eliminate middleman markups by purchasing factory direct steel buildings

• Reduced labor costs compared to conventional factory building methods

• Lower insurance premiums due to fire-resistant properties of factory steel buildings

• Minimal maintenance requirements translate to long-term savings

• Energy-efficient designs reduce operational costs

Durability of Factory Steel Buildings

• Galvanized steel construction ensures factory steel buildings resist corrosion

• Engineered to withstand extreme weather conditions

• Non-combustible materials enhance fire safety in factory building structures

• Resistant to pests, mold, and rot that affect traditional buildings

• Long lifespan often exceeding 50 years with proper maintenance

Customization Options for Factory Building

• Flexible designs accommodate various factory building layouts

• Adjustable clear-span interiors create open workspace

• Multiple exterior finish options for factory direct steel buildings

• Scalable designs allow future expansion

• Custom door and window placements to suit operations

Fast Construction Timeline

• Pre-engineered components of factory steel buildings simplify assembly

• Reduced on-site construction time compared to traditional factory building

• Weather-resistant construction continues during adverse conditions

• Simultaneous site preparation and component fabrication

• Quicker occupancy means faster return on investment

Environmental Benefits

• Recycled steel content in factory direct steel buildings

• Reduced construction waste compared to conventional factory building

• Energy-efficient insulation options available

• Potential for solar panel integration

• Fully recyclable at end of lifespan

Factory Building FAQS

Q: How do factory direct steel buildings compare to other materials in factory building construction?

A: Factory direct steel buildings offer significant advantages over traditional materials like concrete or wood. Steel is lighter yet stronger, reducing foundation costs and construction time. It’s also highly durable, resistant to pests, fire, and corrosion, which lowers long-term maintenance. Unlike wood, steel doesn’t warp or rot, and compared to concrete, it allows for greater design flexibility, enabling large open spaces ideal for factory operations.

Q: What key factors should be considered in the design of factory steel buildings?

A: Designing factory steel buildings requires assessing factors like load capacity, ceiling height, and bay spacing to accommodate machinery and workflow. Ventilation, lighting, and insulation needs are crucial for worker comfort and energy efficiency. Additionally, considering future expansion—such as adding more bays or mezzanines—ensures the building can adapt to business growth. Fire safety features and compliance with local building codes are also non-negotiable.

Q: Can factory direct steel buildings be customized for specific industrial needs?

A: Yes, factory direct steel buildings are highly customizable. Manufacturers can adjust dimensions, roof styles, door and window placements, and interior layouts to fit unique factory requirements. For example, food processing factories may need specialized wall and floor finishes for hygiene, while automotive plants require high bay doors for vehicle entry. Customization also extends to adding mezzanines, loading docks, or climate control systems.

Q: What are the common challenges in maintaining factory buildings made of steel?

A: While factory steel buildings are durable, they face challenges like rust due to moisture exposure, especially in coastal or humid areas. Regularly inspecting and repainting metal surfaces with anti-corrosive coatings helps prevent rust. Another challenge is thermal expansion and contraction, which can cause issues in connections over time. Ensuring proper insulation and periodic structural checks can mitigate these problems and extend the building’s lifespan.

Q: How do factory steel buildings contribute to sustainable factory building practices?

A: Factory steel buildings promote sustainability in multiple ways. Steel is 100% recyclable, reducing waste at the end of a building’s life cycle. Energy-efficient designs, such as insulated metal panels and reflective roofing, can lower heating and cooling costs. Additionally, prefabrication in a factory setting minimizes on-site waste and construction time, reducing the environmental impact associated with traditional construction methods.

Welcome to Hebei HongJi Shunda Steel Structure Engineering Co., Ltd.! Since 2000, we’ve been a leading force in steel structure construction, spanning 52,000 square meters with a robust registered capital of USD$2.5 million. Specializing in the design, manufacture, and installation of steel structures—from warehouses and workshops to poultry sheds and steel homes—we prioritize cost-efficiency through optimized raw material procurement.

Our professional design team, paired with a top-notch production and construction crew, integrates global advanced concepts. This enables us to deliver end-to-end services, ensuring each project meets the highest standards of quality and environmental sustainability. At HongJi Shunda, we’re committed to crafting superior steel structures that transform your vision into reality. Explore more at www.hongjishunda.com .

-

Bolted Connections in Steel Frame Warehouse

NewsNov.17,2025

-

Hay Storage in Farm Metal Buildings

NewsNov.17,2025

-

Advantages of a Steel Portal Frame Shed

NewsNov.17,2025

-

The Erection Process of a Steel Building Hangar

NewsNov.17,2025

-

Energy Efficiency of Steel Dome Garage Kits

NewsNov.17,2025

-

Fire Resistance of Kit Metal Garages

NewsNov.17,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.