- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 11, 2024 09:57 Back to list

The Metal and Steel Factory A Cornerstone of Modern Industry

In today’s rapidly evolving industrial landscape, metal and steel factories play an indispensable role in supporting infrastructure development, manufacturing, and overall economic growth. From towering skyscrapers to intricate automotive components, the products of these factories are integral to the modern world. This article delves into the significance, processes, innovations, and challenges associated with metal and steel factories.

The Importance of Metal and Steel Production

Steel is the most widely used metal in the world, valued for its strength, durability, and versatility. Metal and steel factories are central to countless industries, including construction, automotive, aerospace, and appliances. The global demand for steel continues to rise, driven by urbanization, population growth, and infrastructural development, particularly in emerging economies. The construction sector, which accounts for a significant portion of steel consumption, relies heavily on this material for buildings, bridges, and roads.

Moreover, the automotive industry seeks high-quality steel for manufacturing vehicles that meet safety standards while optimizing fuel efficiency and reducing overall weight. Thus, metal and steel factories not only contribute to technological advancements but also support job creation and economic stability.

The Manufacturing Process

The production of steel usually begins with raw materials such as iron ore, coal, and limestone. The primary methods of steel production include the Basic Oxygen Furnace (BOF) process and the Electric Arc Furnace (EAF) process.

1. Basic Oxygen Furnace (BOF) In this process, molten iron from a blast furnace is combined with scrap steel and then subjected to high-purity oxygen. This reaction oxidizes impurities, resulting in high-quality steel. The BOF process is highly efficient and is predominantly used in large-scale operations.

2. Electric Arc Furnace (EAF) EAF technology involves melting scrap steel using electrical currents. This method has gained popularity due to its energy efficiency and lower carbon footprint, allowing factories to utilize recycled materials while minimizing emissions.

Following the production phase, the steel is shaped and processed into various forms such as sheets, beams, and rods. This involves processes like rolling, forging, and extrusion, each tailored to serve different industrial applications.

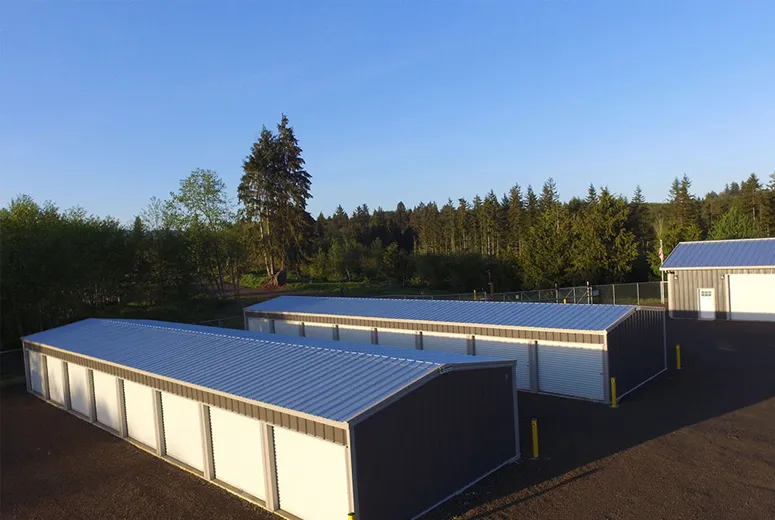

metal & steel factory

Innovations in Metal and Steel Production

As industries seek to reduce their environmental impact, metal and steel factories are undergoing significant transformations. Innovations such as advanced manufacturing techniques, automation, and artificial intelligence (AI) are revolutionizing production efficiency.

For instance, implementing AI-driven analytics helps optimize manufacturing processes, forecast maintenance needs, and enhance quality assurance. Technologies such as 3D printing are also emerging, enabling factories to create complex metal components more rapidly and with less waste.

Sustainability has become a crucial focus within the metal and steel sector. Companies are investing in carbon capture and storage technologies, as well as transitioning to renewable energy sources to power their operations. By doing so, they are working towards reducing greenhouse gas emissions and meeting global sustainability targets.

Challenges Faced by the Industry

Despite the advancements, metal and steel factories face numerous challenges. The fluctuation of raw material prices can significantly impact profitability, necessitating robust supply chain management strategies. Additionally, the highly competitive nature of the global steel market creates pressure to maintain low prices while ensuring high quality.

Labor shortages and the need for skilled workers pose another challenge. As factories increasingly adopt automation and advanced technologies, finding employees with the necessary expertise becomes essential. Training programs and partnerships with educational institutions are critical in bridging this skills gap and creating a future-ready workforce.

Furthermore, regulatory compliance, particularly concerning environmental standards, is becoming more stringent. Factories must stay ahead by investing in cleaner technologies and adhering to best practices in occupational health and safety.

Conclusion

Metal and steel factories are vital to the global economy and are at the forefront of technological and sustainable advancements. As society continues to evolve, these factories must adapt to new challenges while embracing innovations that promote efficiency and sustainability. Through resilience and dedication to continuous improvement, the metal and steel industry will remain a cornerstone of modern industry for years to come.

-

How Do Prefabricated Steel Structures Transform Modern Construction?

NewsJul.14,2025

-

How Do Prefabricated Metal Buildings Redefine Modern Construction?

NewsJul.14,2025

-

How Do Prefab Insulated Metal Buildings and Steel Structures Revolutionize Modern Construction?

NewsJul.14,2025

-

How Do Pre - Engineered Steel Structures Redefine Modern Construction?

NewsJul.14,2025

-

Advancing Modular Construction with Prefabricated Metal Structures

NewsJul.14,2025

-

Advancing Industrial Infrastructure with Prefabricated Steel Solutions

NewsJul.14,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.