- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 03, 2024 12:32 Back to list

The Evolution and Importance of Steel Frame Factories

In today’s rapidly evolving industrial landscape, the role of steel frame factories is more critical than ever. As the backbone of modern construction, these facilities produce the essential structural components that support buildings, bridges, and various infrastructures. This article delves into the significance, processes, and advancements in steel frame factories, highlighting their contribution to global development.

The Significance of Steel Framework

Steel has emerged as the material of choice in construction due to its unparalleled strength-to-weight ratio, durability, and versatility. Steel frames provide the necessary support for structures, enabling architects and engineers to design buildings that stand tall and withstand natural forces such as wind, earthquakes, and heavy snow loads. The precision and stability of steel frames lead to safer constructions and are fundamental in building skyscrapers, factories, and residential complexes.

The shift towards urbanization and increasing population numbers necessitate efficient construction solutions. Steel frame factories cater to this demand by ensuring that steel components are produced at scale, delivered on time, and ready for assembly. This efficiency not only reduces construction time but also minimizes waste, leading to more sustainable building practices.

Processes Involved in Steel Frame Production

The production of steel frames involves several meticulous processes. Initially, raw materials like iron ore and recycled steel are sourced. These materials undergo smelting, where they are melted down and purified to obtain steel of the required quality. Following this, the steel is molded into different shapes and sizes – including beams, columns, and trusses – that will form the framework of a building.

Once shaped, the steel components are subjected to various treatments to enhance their durability. Techniques such as galvanization, where steel is coated with zinc, protect against corrosion, a significant concern in construction. Additionally, factories often employ advanced technologies like laser cutting and automated welding to ensure precision during fabrication.

Quality control is paramount in steel frame manufacturing. Factories must adhere to strict standards and regulations to guarantee that each piece can withstand the stresses it will face in the field. This involves rigorous testing for strength, durability, and resilience, ensuring that safety is prioritized from the manufacturing stage itself.

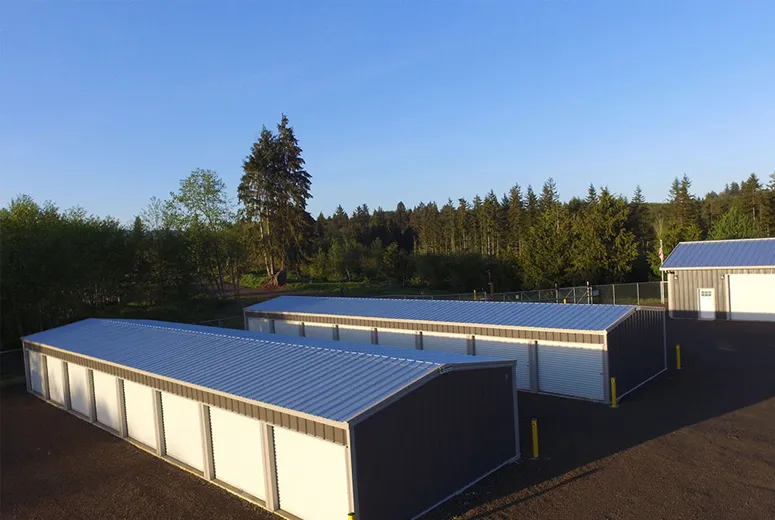

steel frame factory

Innovations and Technological Advancements

The steel frame industry has not remained static; it has embraced technological advancements to enhance production efficiency and sustainability. The integration of computer-aided design (CAD) and building information modeling (BIM) allows for more precise planning and execution of steel frame projects. These technologies enable the simulation of construction processes, helping to identify potential issues before actual assembly begins.

Moreover, automation and robotics have revolutionized the manufacturing process. Automated machines now handle repetitive tasks, increasing production speed and reducing labor costs, while robots assist in welding and assembly, enhancing accuracy. The use of sustainable practices, including energy-efficient processes and waste reduction techniques, further highlights the industry's commitment to environmental responsibility.

Future Directions

Looking ahead, the steel frame factory model will likely evolve even further. As the construction industry focuses more on sustainability, developments such as the use of low-carbon steel production methods and the incorporation of recycled materials will gain traction. Factories that adapt to these trends can reduce their carbon footprint and promote sustainability in construction practices.

Additionally, as structures become more complex, the demand for customized steel frames will increase. Factories that can swiftly accommodate unique designs without compromising quality will find themselves at a competitive advantage. The emphasis on prefabrication will also continue to grow, with complete steel frameworks being manufactured in factories and then transported to construction sites for rapid assembly.

Conclusion

Steel frame factories play an essential role in modern construction, providing the vital components that form the structural integrity of buildings and infrastructure. With advancements in technology and an increasing focus on sustainability, these factories are poised to meet the demands of the future. As we continue to build a world that requires resilience and efficiency, the significance of steel framed structures will only amplify, underscoring the importance of steel frame factories in shaping our architectural landscape.

-

How Do Prefabricated Steel Structures Transform Modern Construction?

NewsJul.14,2025

-

How Do Prefabricated Metal Buildings Redefine Modern Construction?

NewsJul.14,2025

-

How Do Prefab Insulated Metal Buildings and Steel Structures Revolutionize Modern Construction?

NewsJul.14,2025

-

How Do Pre - Engineered Steel Structures Redefine Modern Construction?

NewsJul.14,2025

-

Advancing Modular Construction with Prefabricated Metal Structures

NewsJul.14,2025

-

Advancing Industrial Infrastructure with Prefabricated Steel Solutions

NewsJul.14,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.