- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 30, 2024 13:51 Back to list

The Importance of Steel Manufacturing and Warehousing in Modern Industry

Steel manufacturing is a vital backbone of modern industrial economies, playing an essential role in various sectors, from construction and automotive to infrastructure and machinery. The robustness and versatility of steel make it the material of choice for producing everything from skyscrapers to bridges and vehicles. In the face of globalization and rapid technological advancement, the processes surrounding steel manufacturing and warehousing have evolved significantly, making them crucial components in supply chain management.

The Importance of Steel Manufacturing and Warehousing in Modern Industry

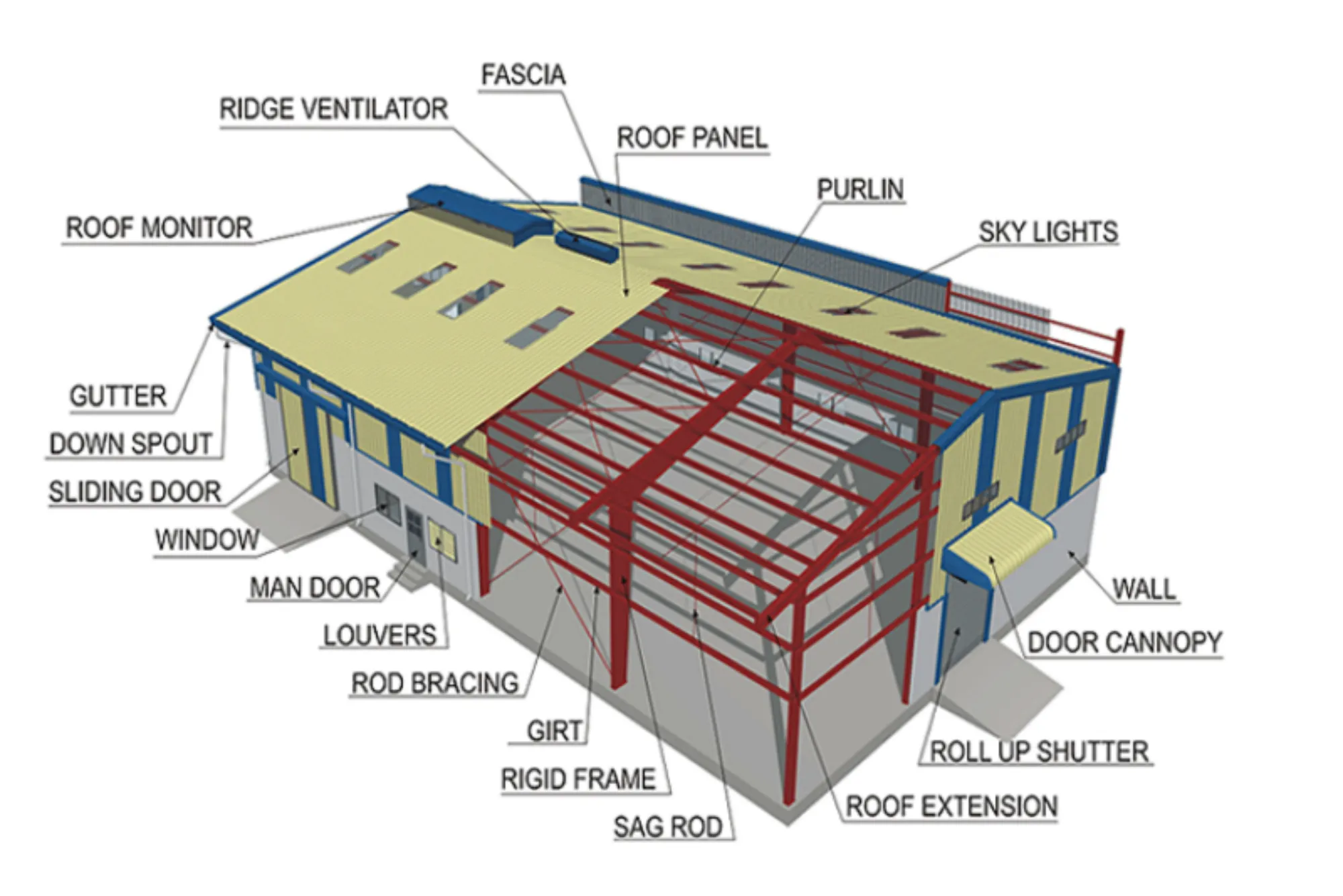

Once steel is manufactured, the next critical step is warehousing. Effective steel warehousing solutions are essential to facilitate the smooth flow of materials in the supply chain. Given the bulkiness and weight of steel products, the warehousing process involves specific strategies to optimize space and enhance efficiency. Modern steel warehouses utilize an array of techniques, including automated storage and retrieval systems, inventory management software, and strategic layout designs to minimize space and reduce handling times.

steel manufacturing & warehouse

The interconnectedness of steel manufacturing and warehousing is particularly significant in just-in-time (JIT) inventory systems, which aim to reduce holding costs by aligning material orders with production schedules. By minimizing storage times and maximizing the efficiency of the supply chain, manufacturers can respond faster to market demands while reducing waste. This synchronization is particularly critical in industries where the rapid turnaround of materials is necessary to maintain competitive advantages.

Furthermore, steel warehouses serve as distribution centers, providing vital logistical support. Proper management of inventory levels ensures that manufacturers can procure steel products promptly, preventing potential production bottlenecks. In recent years, a focus on digitalization and the adoption of advanced technologies such as artificial intelligence and the Internet of Things (IoT) have further refined warehousing practices. These technologies facilitate real-time tracking of inventory, improving decision-making and operational efficiency.

The collaborative relationship between steel manufacturers and warehousing facilities cannot be overstated. As markets evolve and the demand for steel fluctuates, adaptability becomes crucial. Continuous assessments of both manufacturing processes and warehousing capabilities are paramount to achieving operational excellence. The integration of marketing strategies, customer feedback, and advanced analytics plays a role in shaping the future of steel manufacturing and warehousing.

In conclusion, steel manufacturing and warehousing constitute two interlinked pillars in the industrial ecosystem. As the world progresses toward more sustainable and efficient practices, the steel industry must adapt to meet these emerging demands. By embracing technological advancements and optimizing supply chain processes, steel manufacturers and warehouses can ensure their vital role in supporting global infrastructure and development well into the future. The enduring significance of steel as a foundational material will continue to drive innovation and growth in manufacturing and warehousing sectors, reflecting their indispensable importance in modern industry.

-

How Do Prefabricated Steel Structures Transform Modern Construction?

NewsJul.14,2025

-

How Do Prefabricated Metal Buildings Redefine Modern Construction?

NewsJul.14,2025

-

How Do Prefab Insulated Metal Buildings and Steel Structures Revolutionize Modern Construction?

NewsJul.14,2025

-

How Do Pre - Engineered Steel Structures Redefine Modern Construction?

NewsJul.14,2025

-

Advancing Modular Construction with Prefabricated Metal Structures

NewsJul.14,2025

-

Advancing Industrial Infrastructure with Prefabricated Steel Solutions

NewsJul.14,2025

Products categories

Our Latest News

We have a professional design team and an excellent production and construction team.